Table of Contents

Benefits of Using OEM Injection Molding for Plastic Products

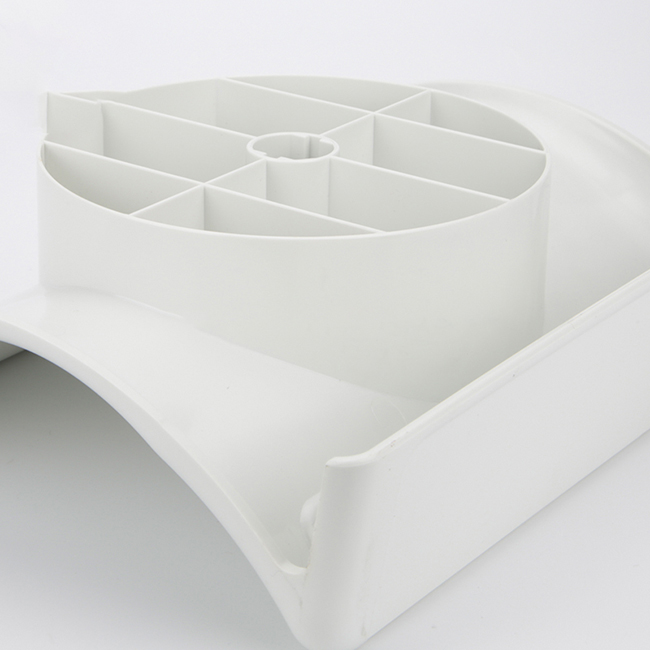

OEM injection molding is a popular manufacturing process used to produce plastic products for a wide range of industries. This method involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. OEM injection molding offers numerous benefits for businesses looking to create high-quality plastic products efficiently and cost-effectively.

One of the key advantages of using OEM injection molding is the ability to produce complex and intricate designs with high precision. The mold cavity can be customized to create intricate shapes and features that would be difficult or impossible to achieve with other manufacturing methods. This level of precision allows for the production of plastic products with tight tolerances and consistent quality.

Another benefit of OEM injection molding is the ability to produce large quantities of plastic products quickly and efficiently. Once the mold is created, the injection molding process can be automated to produce hundreds or even thousands of identical parts in a short amount of time. This high production capacity makes OEM injection molding an ideal choice for businesses looking to scale up their manufacturing operations.

In addition to speed and precision, OEM injection molding offers cost savings for businesses producing plastic products. The initial investment in creating the mold may be higher than other manufacturing methods, but the per-unit cost of production is typically lower. This cost efficiency is especially beneficial for businesses producing large quantities of plastic products, as the savings can quickly add up over time.

OEM injection molding also allows for a wide range of materials to be used in the production of plastic products. Different types of plastics can be used depending on the specific requirements of the product, such as strength, flexibility, or heat resistance. This versatility in material selection gives businesses the flexibility to create plastic products that meet their exact specifications and performance requirements.

Furthermore, OEM injection molding is a sustainable manufacturing process that produces minimal waste. The excess plastic material that is generated during the molding process can be recycled and reused, reducing the environmental impact of production. This eco-friendly aspect of OEM injection molding is increasingly important for businesses looking to minimize their carbon footprint and meet sustainability goals.

Overall, OEM injection molding offers numerous benefits for businesses looking to produce high-quality plastic products efficiently and cost-effectively. From precision and speed to cost savings and material versatility, this manufacturing process provides a competitive advantage for businesses in a wide range of industries. By leveraging the advantages of OEM injection molding, businesses can create plastic products that meet their exact specifications and performance requirements, while also reducing waste and minimizing their environmental impact.

How to Choose the Right OEM Injection Molding Partner for Your Plastic Product Needs

When it comes to manufacturing plastic products, choosing the right OEM injection molding partner is crucial. OEM injection molding involves the production of plastic parts by injecting molten material into a mold. This process requires precision, expertise, and attention to detail to ensure that the final product meets the desired specifications.

One of the most important factors to consider when selecting an OEM injection molding partner is their experience and expertise in the industry. Look for a company that has a proven track record of delivering high-quality plastic products to their clients. A reputable partner will have a team of skilled engineers and technicians who are knowledgeable about the latest technologies and techniques in injection molding.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

In addition to experience, it is essential to consider the capabilities of the OEM injection molding partner. Make sure that they have the equipment and resources necessary to handle your project efficiently and effectively. This includes having a variety of injection molding machines with different capacities and capabilities to accommodate your specific needs.

Communication is another key factor to consider when choosing an OEM injection molding partner. A good partner will keep you informed throughout the entire manufacturing process, providing updates on the progress of your project and addressing any concerns or questions you may have. Clear and open communication is essential for ensuring that the final product meets your expectations.

Quality control is also a critical aspect to consider when selecting an OEM injection molding partner. Look for a company that has strict quality control measures in place to ensure that each plastic product meets the highest standards of quality and durability. This includes conducting thorough inspections and tests throughout the manufacturing process to identify and address any potential issues.

Cost is another important consideration when choosing an OEM injection molding partner. While it is essential to find a partner that offers competitive pricing, it is equally important to consider the overall value they provide. Look for a company that offers a balance of quality, expertise, and affordability to ensure that you get the best possible results for your investment.

When evaluating potential OEM injection molding partners, be sure to ask for samples of their work and references from past clients. This will give you a better understanding of their capabilities and reputation in the industry. Additionally, consider visiting their facilities to see their operation firsthand and meet with their team to discuss your project in detail.

Ultimately, choosing the right OEM injection molding partner for your plastic product needs requires careful consideration and research. By taking the time to evaluate each potential partner based on their experience, capabilities, communication, quality control, and cost, you can ensure that your project is in good hands. A reliable and experienced partner will work closely with you to bring your vision to life and deliver high-quality plastic products that meet your specifications and exceed your expectations.