Advantages of Using Injection Blow Molding for Plastic Machine Molding

Plastic machine molding is a widely used manufacturing process in the production of plastic products. One of the most popular methods of plastic machine molding is injection blow molding. This process involves injecting molten plastic into a mold cavity, where it is then blown into the desired shape. Injection blow molding offers several advantages over other molding techniques, making it a preferred choice for many manufacturers.

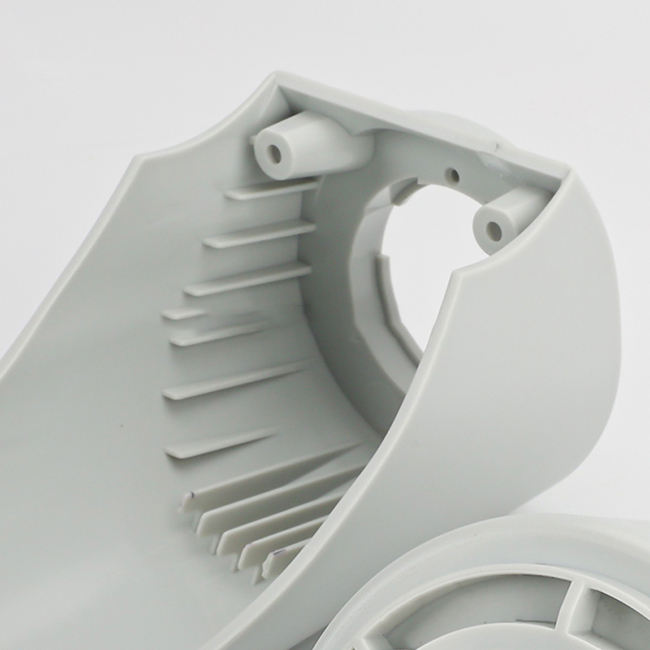

One of the key advantages of injection blow molding is its ability to produce complex and intricate shapes with high precision. The process allows for the creation of detailed features and intricate designs that may be difficult or impossible to achieve with other molding techniques. This makes injection blow molding ideal for producing products with unique shapes and designs, such as bottles, containers, and other hollow plastic items.

Another advantage of injection blow molding is its efficiency and cost-effectiveness. The process is highly automated, allowing for fast and efficient production with minimal labor costs. This makes injection blow molding a cost-effective option for large-scale production runs, as it can produce a high volume of products in a relatively short amount of time. Additionally, the use of automated machinery reduces the risk of human error, resulting in consistent and high-quality products.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

Injection blow molding also offers excellent material distribution and uniform wall thickness, resulting in strong and durable plastic products. The process ensures that the molten plastic is evenly distributed throughout the mold cavity, preventing weak spots or inconsistencies in the final product. This results in plastic products that are strong, durable, and resistant to wear and tear, making them ideal for a wide range of applications.

Furthermore, injection blow molding is a versatile process that can accommodate a variety of materials, including thermoplastics, thermosets, and elastomers. This flexibility allows manufacturers to choose the most suitable material for their specific application, ensuring that the final product meets the desired performance requirements. Additionally, injection blow molding can produce products with a wide range of sizes and shapes, making it suitable for a diverse range of industries and applications.

In conclusion, injection blow molding offers several advantages for plastic machine molding, including the ability to produce complex shapes with high precision, efficiency and cost-effectiveness, excellent material distribution and uniform wall thickness, and versatility in material selection. These advantages make injection blow molding a preferred choice for many manufacturers looking to produce high-quality plastic products in a cost-effective and efficient manner. Whether you are producing bottles, containers, or other hollow plastic items, injection blow molding is a reliable and effective process that can meet your manufacturing needs.