Benefits of Using Plastic Injection Molding Parts Covers

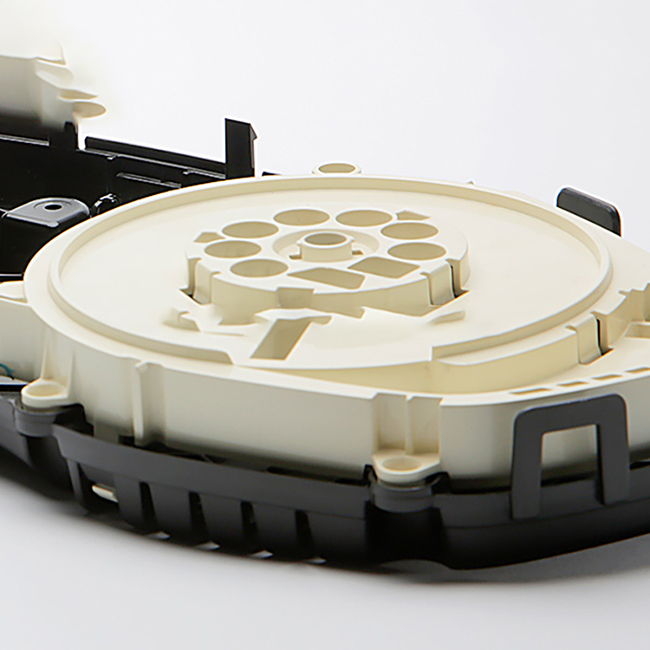

Plastic injection molding parts covers are a popular choice for a wide range of industries due to their numerous benefits. These covers are used to protect and enhance the appearance of various products, from electronic devices to automotive components. In this article, we will explore the advantages of using plastic injection molding parts covers and why they are a preferred option for many manufacturers.

One of the key benefits of plastic injection molding parts covers is their durability. These covers are made from high-quality materials that are designed to withstand wear and tear, making them ideal for use in demanding environments. Whether they are exposed to harsh weather conditions or frequent handling, plastic injection molding parts covers are built to last.

In addition to their durability, plastic injection molding parts covers are also lightweight and easy to install. This makes them a cost-effective solution for manufacturers looking to protect their products without adding unnecessary weight or complexity. The lightweight nature of these covers also makes them easy to transport and handle, reducing the overall cost of production.

Another advantage of plastic injection molding parts covers is their versatility. These covers can be customized to fit a wide range of shapes and sizes, making them suitable for a variety of applications. Whether you need a cover for a small electronic device or a large automotive component, plastic injection molding parts covers can be tailored to meet your specific requirements.

Furthermore, plastic injection molding parts covers offer excellent design flexibility. Manufacturers can choose from a wide range of colors, finishes, and textures to create a cover that complements their product’s aesthetics. This level of customization allows manufacturers to differentiate their products in a competitive market and create a unique brand identity.

Plastic injection molding parts covers are also highly efficient to produce. The injection molding process allows for high-volume production at a fast pace, reducing lead times and overall production costs. This efficiency makes plastic injection molding parts covers a cost-effective solution for manufacturers looking to streamline their production processes.

Additionally, plastic injection molding parts covers are environmentally friendly. These covers can be recycled and reused, reducing waste and minimizing the impact on the environment. By choosing plastic injection molding parts covers, manufacturers can demonstrate their commitment to sustainability and responsible manufacturing practices.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

In conclusion, plastic injection molding parts covers offer a wide range of benefits for manufacturers looking to protect and enhance their products. From durability and versatility to design flexibility and efficiency, these covers are a preferred option for many industries. By choosing plastic injection molding parts covers, manufacturers can ensure that their products are well-protected, visually appealing, and cost-effective to produce.