Table of Contents

Benefits of Using Plastic Injection Molding Injection Kits for Small-Scale Production

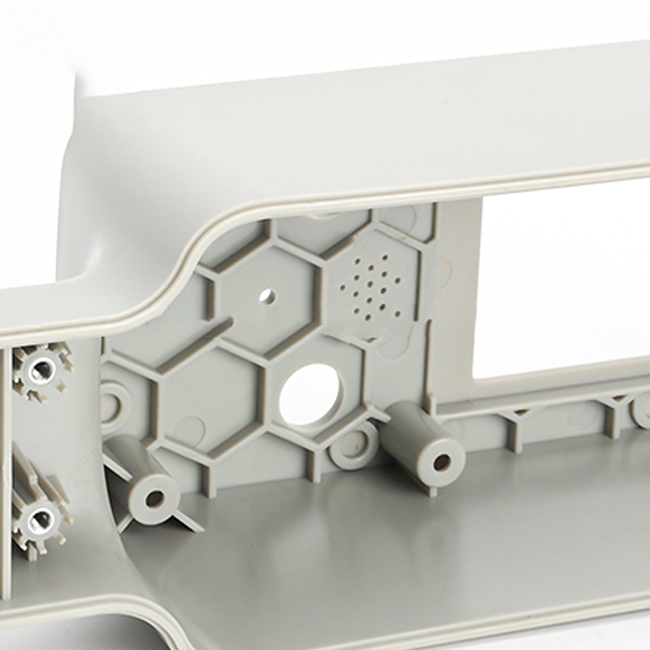

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is commonly used to produce a wide range of plastic products, from small components to large parts. While traditional plastic injection molding is typically done on a large scale in industrial settings, there are now plastic injection molding injection kits available for small-scale production.

One of the main benefits of using plastic injection molding injection kits for small-scale production is cost-effectiveness. Traditional plastic injection molding requires expensive machinery and molds, making it impractical for small businesses or individuals looking to produce small quantities of plastic parts. With injection kits, however, the cost of entry into plastic injection molding is significantly lower, making it more accessible to those with limited resources.

Another advantage of using plastic injection molding injection kits is the flexibility they offer in terms of design and customization. Traditional plastic injection molding often requires large production runs to be cost-effective, limiting the ability to make changes to the design or produce small quantities of custom parts. Injection kits, on the other hand, allow for quick and easy changes to the mold, making it possible to produce small batches of custom parts without incurring high costs.

In addition to cost-effectiveness and flexibility, plastic injection molding injection kits also offer faster turnaround times compared to traditional plastic injection molding. With traditional molding processes, it can take weeks or even months to produce a mold and set up production. Injection kits, on the other hand, can be set up and ready to use in a matter of days, allowing for faster production of plastic parts.

Furthermore, plastic injection molding injection kits are easy to use and require minimal training to operate. Traditional plastic injection molding machinery can be complex and require specialized knowledge to operate effectively. Injection kits, on the other hand, are designed to be user-friendly and can be operated by individuals with basic knowledge of the injection molding process.

Overall, plastic injection molding injection kits offer a cost-effective, flexible, and efficient solution for small-scale production of plastic parts. Whether you are a small business looking to produce custom parts or an individual looking to bring your design ideas to life, injection kits provide a practical and accessible way to get started with plastic injection molding. With their ease of use, quick turnaround times, and ability to produce custom parts in small quantities, injection kits are a valuable tool for anyone looking to enter the world of plastic injection molding.

How to Choose the Right Plastic Injection Molding Injection Kit for Your Project

Plastic injection molding is a popular manufacturing process used to create a wide range of products, from automotive parts to medical devices. If you are considering using plastic injection molding for your project, one of the first things you will need to do is choose the right injection kit.

There are many factors to consider when selecting a plastic injection molding injection kit, including the type of plastic you will be using, the size and complexity of your project, and your budget. In this article, we will discuss some key considerations to keep in mind when choosing an injection kit for your project.

One of the most important factors to consider when choosing a plastic injection molding injection kit is the type of plastic you will be using. Different types of plastics have different properties, such as strength, flexibility, and heat resistance. Some plastics are better suited for certain types of projects than others, so it is important to choose a kit that is compatible with the type of plastic you will be using.

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

Another important factor to consider is the size and complexity of your project. Some injection kits are designed for small, simple projects, while others are better suited for larger, more complex projects. If you are working on a small project, you may be able to get by with a basic injection kit. However, if you are working on a larger or more complex project, you may need a more advanced kit with additional features and capabilities.

Your budget is also an important consideration when choosing a plastic injection molding injection kit. Injection kits can vary widely in price, so it is important to set a budget before you start shopping. Keep in mind that while a more expensive kit may have more features and capabilities, it may not always be necessary for your project. Consider your budget carefully and choose a kit that offers the features you need at a price you can afford.

When choosing a plastic injection molding injection kit, it is also important to consider the reputation of the manufacturer. Look for a manufacturer with a good reputation for producing high-quality injection kits that are reliable and durable. Reading reviews and talking to other customers can help you determine which manufacturers are the most reputable and reliable.

In conclusion, choosing the right plastic injection molding injection kit for your project is an important decision that requires careful consideration. Consider factors such as the type of plastic you will be using, the size and complexity of your project, your budget, and the reputation of the manufacturer. By taking the time to research and compare different injection kits, you can ensure that you choose a kit that meets your needs and helps you achieve the best results for your project.