Table of Contents

Benefits of Using Plastic Injection Molding for Coffee Cup Production

Plastic injection molding is a widely used manufacturing process for producing a variety of plastic products, including coffee cups. This method offers numerous benefits that make it an ideal choice for coffee cup production.

One of the key advantages of plastic injection molding is its cost-effectiveness. The process allows for high-volume production at a relatively low cost per unit, making it a cost-efficient option for producing large quantities of coffee cups. This can be particularly beneficial for businesses looking to mass-produce coffee cups for sale or distribution.

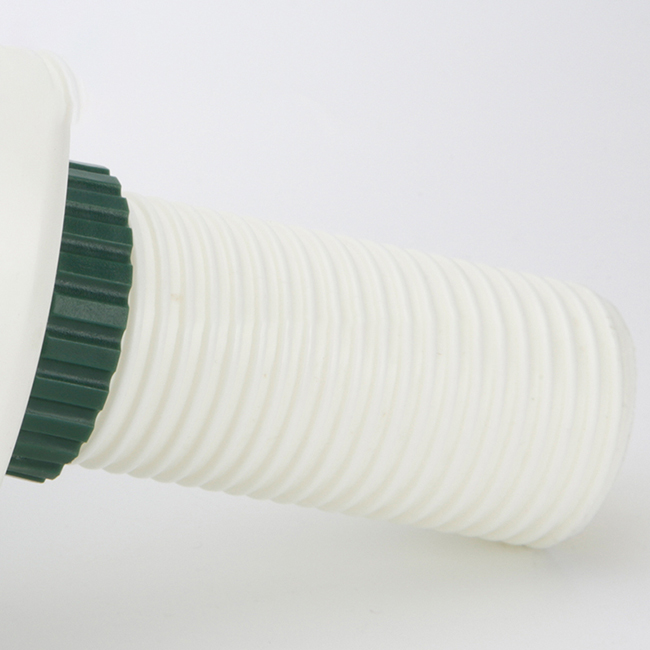

In addition to cost savings, plastic injection molding offers excellent precision and consistency in the production of coffee cups. The process involves injecting molten plastic material into a mold cavity, which is then cooled and solidified to form the final product. This results in coffee cups that are uniform in size, shape, and quality, ensuring a consistent end product that meets the desired specifications.

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

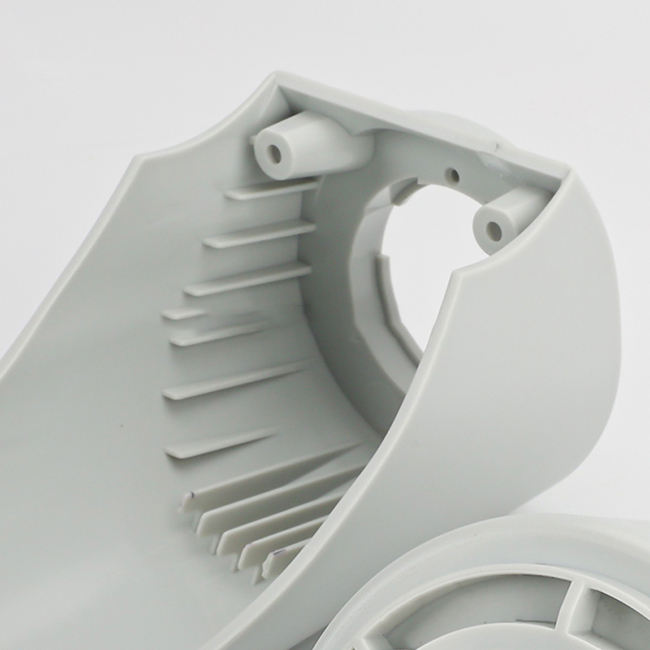

Furthermore, plastic injection molding allows for the production of coffee cups with intricate designs and complex shapes. The versatility of the process enables manufacturers to create custom molds that can produce coffee cups with unique features, such as handles, logos, or textured surfaces. This flexibility in design capabilities makes plastic injection molding a popular choice for creating coffee cups that stand out in the market.

Another benefit of using plastic injection molding for coffee cup production is the durability and strength of the final product. Plastic materials used in injection molding are known for their resilience and resistance to wear and tear, making them ideal for everyday use. Coffee cups manufactured through this process are able to withstand repeated use and washing without losing their shape or integrity, ensuring long-lasting performance for the end user.

Additionally, plastic injection molding is a fast and efficient process that allows for quick turnaround times in production. The high-speed nature of the process enables manufacturers to produce coffee cups in large quantities within a short period of time, meeting tight deadlines and demand fluctuations in the market. This rapid production capability is essential for businesses looking to stay competitive and responsive to consumer needs.

Moreover, plastic injection molding is a sustainable manufacturing method that can help reduce waste and environmental impact. The process generates minimal scrap material, as any excess plastic can be recycled and reused in future production runs. This eco-friendly approach to manufacturing aligns with growing consumer demand for sustainable products and practices, making plastic injection molding an attractive option for businesses looking to minimize their carbon footprint.

In conclusion, plastic injection molding offers a range of benefits for coffee cup production, including cost-effectiveness, precision, versatility in design, durability, efficiency, and sustainability. These advantages make it a preferred choice for businesses looking to manufacture high-quality coffee cups that meet consumer expectations and market demands. By leveraging the benefits of plastic injection molding, manufacturers can create coffee cups that are not only functional and aesthetically pleasing but also environmentally friendly and economically viable.

Environmental Impact of Plastic Injection Molding in Coffee Cup Manufacturing

Plastic injection molding is a widely used manufacturing process in the production of various products, including coffee cups. While this method offers efficiency and cost-effectiveness, it also comes with environmental implications that cannot be ignored. In this article, we will explore the environmental impact of plastic injection molding in coffee cup manufacturing.

One of the primary concerns with plastic injection molding is the use of plastic materials, which are derived from fossil fuels. The extraction and processing of these materials contribute to greenhouse gas emissions and environmental degradation. Additionally, the production of plastic materials requires a significant amount of energy, further exacerbating the carbon footprint of the manufacturing process.

Once the plastic materials are molded into coffee cups, they often end up in landfills after use. Plastic is not biodegradable and can take hundreds of years to decompose. As a result, plastic waste accumulates in landfills, pollutes waterways, and harms wildlife. The disposal of plastic coffee cups also contributes to the global plastic pollution crisis, which poses a serious threat to the environment and human health.

In addition to the environmental impact of plastic materials, the manufacturing process itself can also have negative consequences. Plastic injection molding requires the use of machinery and equipment that consume energy and produce emissions. The operation of these machines contributes to air pollution and further exacerbates the carbon footprint of the manufacturing process.

To mitigate the environmental impact of plastic injection molding in coffee cup manufacturing, companies can take several steps. One approach is to use recycled plastic materials in the production of coffee cups. By incorporating recycled content into their products, companies can reduce the demand for virgin plastic materials and decrease the environmental footprint of the manufacturing process.

Another strategy is to optimize the manufacturing process to minimize energy consumption and emissions. Companies can invest in energy-efficient machinery, implement waste reduction measures, and adopt sustainable practices to reduce their environmental impact. By prioritizing sustainability in their operations, companies can minimize the negative consequences of plastic injection molding in coffee cup manufacturing.

Furthermore, companies can explore alternative materials and manufacturing methods that are more environmentally friendly. For example, biodegradable materials such as PLA (polylactic acid) can be used as an alternative to traditional plastics in coffee cup production. Biodegradable materials break down more easily in the environment, reducing the long-term impact of plastic waste.

In conclusion, the environmental impact of plastic injection molding in coffee cup manufacturing is a significant concern that requires attention and action. Companies must prioritize sustainability and adopt practices that minimize the negative consequences of plastic materials and manufacturing processes. By using recycled materials, optimizing energy consumption, and exploring alternative materials, companies can reduce their environmental footprint and contribute to a more sustainable future. It is essential for the industry to address these challenges and work towards a more environmentally friendly approach to coffee cup manufacturing.