Benefits of Plastic Parts Injection Molding Service

Plastic parts injection molding service is a widely used manufacturing process that offers a multitude of benefits for businesses looking to produce high-quality plastic components. This process involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. The resulting plastic parts are durable, precise, and cost-effective, making injection molding a popular choice for a wide range of industries.

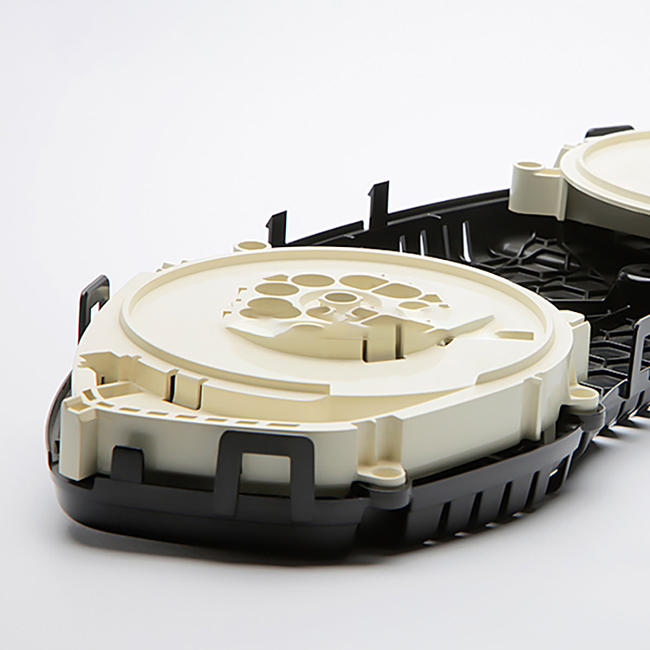

One of the key benefits of plastic parts injection molding service is its ability to produce complex shapes with high precision. The mold cavity can be designed to create intricate details and features that would be difficult or impossible to achieve with other manufacturing methods. This level of precision ensures that the final plastic parts meet the exact specifications required for the intended application.

In addition to precision, plastic parts injection molding service offers excellent repeatability and consistency. Once the mold is set up and the process parameters are dialed in, the injection molding machine can produce identical parts with minimal variation. This consistency is crucial for industries that require large quantities of plastic components that must meet strict quality standards.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

Another advantage of plastic parts injection molding service is its cost-effectiveness. The initial tooling costs for creating the mold may be higher compared to other manufacturing methods, but once the mold is made, the per-unit cost of each plastic part is relatively low. This makes injection molding a cost-effective solution for high-volume production runs, as the economies of scale can drive down the overall cost per part.

Furthermore, plastic parts injection molding service is a fast and efficient process. The cycle time for each injection molding cycle is typically short, allowing for high production output rates. This rapid production speed can help businesses meet tight deadlines and respond quickly to changes in demand.

Additionally, plastic parts injection molding service offers a wide range of material options to choose from. Different types of thermoplastics can be used in the injection molding process, each with its own unique properties and characteristics. This versatility allows businesses to select the most suitable material for their specific application, whether it requires strength, flexibility, heat resistance, or other specific attributes.

Moreover, plastic parts injection molding service is a sustainable manufacturing option. The scrap material generated during the injection molding process can be recycled and reused, reducing waste and minimizing environmental impact. Additionally, the energy efficiency of injection molding machines helps lower energy consumption and carbon emissions compared to other manufacturing methods.

In conclusion, plastic parts injection molding service offers a multitude of benefits for businesses looking to produce high-quality plastic components. From precision and consistency to cost-effectiveness and sustainability, injection molding is a versatile and efficient manufacturing process that can meet the needs of a wide range of industries. Whether producing small, intricate parts or large, complex components, businesses can rely on plastic parts injection molding service to deliver reliable and cost-effective solutions.