Benefits of Using Plastic Injection Molding Funnel in Manufacturing Processes

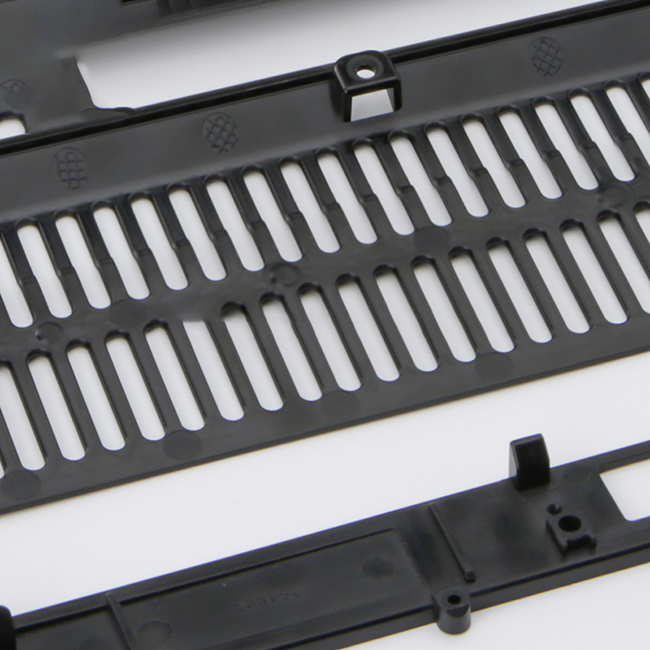

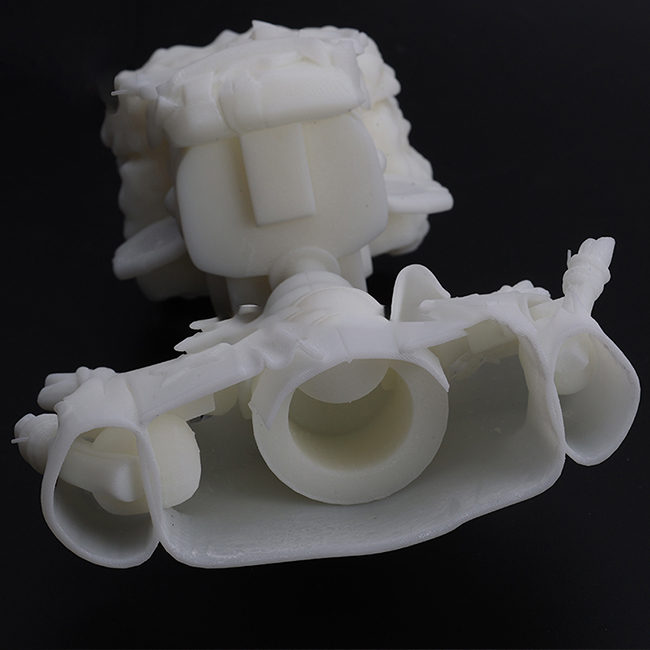

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. This process allows for the production of complex and intricate plastic parts with high precision and consistency. One essential tool in plastic injection molding is the funnel, which plays a crucial role in guiding the flow of molten plastic into the mold cavity.

The plastic injection molding funnel is designed to channel the molten plastic from the injection unit into the mold cavity. It helps to ensure that the plastic is distributed evenly throughout the mold, resulting in a uniform and high-quality finished product. The funnel also helps to prevent air bubbles and other defects from forming in the plastic part, which can compromise its structural integrity.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

One of the key benefits of using a plastic injection molding funnel is its ability to improve the efficiency of the manufacturing process. By guiding the flow of molten plastic into the mold cavity, the funnel helps to reduce waste and minimize the risk of production errors. This can result in significant cost savings for manufacturers, as they can produce more parts in less time and with fewer defects.

Another advantage of using a plastic injection molding funnel is its versatility. Funnel designs can be customized to meet the specific requirements of different plastic parts and molds. This flexibility allows manufacturers to produce a wide range of products with varying shapes, sizes, and complexities. Whether it’s a small, intricate component or a large, complex part, a well-designed funnel can help to ensure that the plastic is distributed evenly and accurately in the mold cavity.

In addition to improving efficiency and versatility, plastic injection molding funnels also help to enhance the overall quality of the finished product. By guiding the flow of molten plastic into the mold cavity, the funnel helps to reduce the risk of defects such as warping, sink marks, and voids. This results in plastic parts that are more consistent, durable, and aesthetically pleasing.

Furthermore, using a plastic injection molding funnel can also help to extend the lifespan of the mold. By ensuring that the plastic is distributed evenly and smoothly, the funnel helps to reduce wear and tear on the mold cavity. This can help to prolong the life of the mold, saving manufacturers time and money on mold maintenance and replacement.

Overall, the benefits of using a plastic injection molding funnel in manufacturing processes are clear. From improving efficiency and versatility to enhancing product quality and extending mold lifespan, a well-designed funnel can make a significant impact on the success of a plastic injection molding operation. By investing in high-quality funnels and incorporating them into their manufacturing processes, manufacturers can achieve better results and stay ahead of the competition in today’s fast-paced and competitive market.