Benefits of Using ABS, PP, PC, and PA66 Plastic Injection Molding Parts in Manufacturing

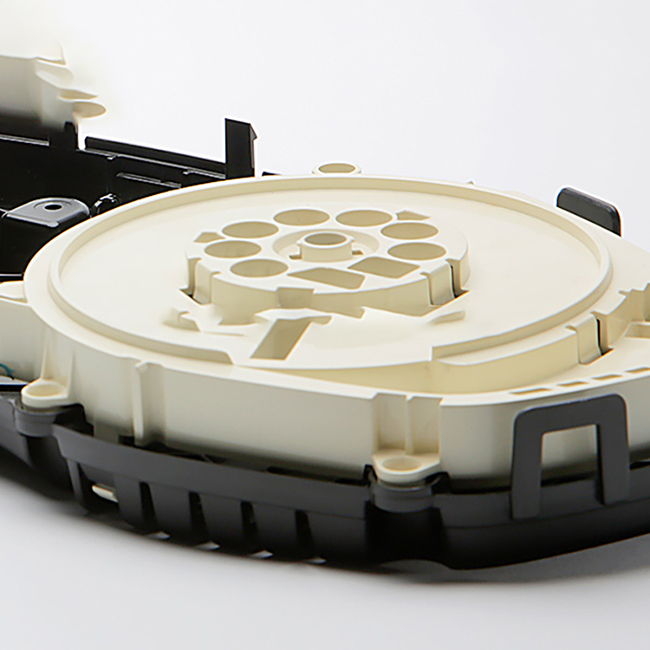

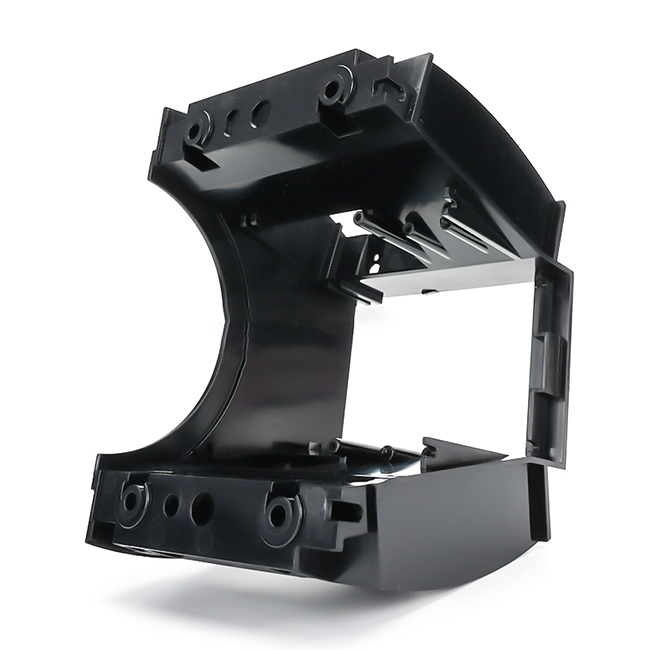

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process allows for the production of complex and intricate parts with high precision and consistency. ABS, PP, PC, and PA66 are some of the most commonly used materials in plastic injection molding due to their unique properties and benefits.

ABS, or Acrylonitrile Butadiene Styrene, is a versatile thermoplastic that is known for its high impact resistance and toughness. It is commonly used in the automotive, electronics, and consumer goods industries for applications that require durability and strength. ABS plastic injection molding parts are lightweight, yet strong, making them ideal for a wide range of products.

| Product Name | OEM Plastic injection molding Parts |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

PP, or Polypropylene, is another popular material used in plastic injection molding. It is a lightweight and flexible thermoplastic that is resistant to chemicals and moisture. PP plastic injection molding parts are commonly used in the packaging, automotive, and medical industries due to their excellent chemical resistance and low moisture absorption properties.

PC, or Polycarbonate, is a transparent thermoplastic that is known for its high impact resistance and optical clarity. It is commonly used in the automotive, aerospace, and electronics industries for applications that require high strength and transparency. PC plastic injection molding parts are ideal for products that need to withstand harsh environments and maintain their clarity over time.

PA66, or Polyamide 66, is a strong and durable thermoplastic that is known for its high tensile strength and heat resistance. It is commonly used in the automotive, electrical, and industrial industries for applications that require high mechanical strength and thermal stability. PA66 plastic injection molding parts are ideal for products that need to withstand high temperatures and heavy loads.

One of the main benefits of using ABS, PP, PC, and PA66 plastic injection molding parts is their cost-effectiveness. These materials are readily available and can be easily molded into complex shapes, reducing the need for additional machining or finishing processes. This results in lower production costs and faster lead times, making plastic injection molding an efficient manufacturing solution for a wide range of industries.

In addition to cost-effectiveness, ABS, PP, PC, and PA66 plastic injection molding parts offer excellent mechanical properties. These materials are known for their high strength, impact resistance, and durability, making them ideal for applications that require reliable and long-lasting components. Whether it’s a small electronic device or a large automotive part, ABS, PP, PC, and PA66 plastic injection molding parts can meet the demanding requirements of various industries.

Furthermore, ABS, PP, PC, and PA66 plastic injection molding parts are highly customizable. Manufacturers can easily adjust the material composition, color, and surface finish of these parts to meet specific design requirements. This flexibility allows for the production of unique and innovative products that stand out in the market.

Overall, ABS, PP, PC, and PA66 plastic injection molding parts offer a wide range of benefits for manufacturers looking to produce high-quality and cost-effective components. From their excellent mechanical properties to their customization options, these materials are a versatile and reliable choice for a variety of industries. By leveraging the advantages of ABS, PP, PC, and PA66 plastic injection molding parts, manufacturers can streamline their production processes and deliver superior products to their customers.