Table of Contents

فوائد استخدام قوالب حقن البلاستيك لطعم الصيد

كيفية اختيار المادة البلاستيكية المناسبة لمعدات صيد الأسماك بالحقن

تشطيب السطح

لمسة نهائية مصقولة / طباعة سليك / لمسة نهائية للملمس / طلاء مطاطي / تشطيب لامع / طلاء / شاشة سليك / طباعة وسادة / طلاء EMI / طلاء إلكتروني / وضع علامة بالليزر / إلخ.

| عملية الإنتاج | الطلبيات-المواد الخام-فحص جودة الإنتاج-التعبئة-الشحن |

| التكنولوجيا | الرغوة / الحقن العادي / قولبة الرغوة الإنشائية / القولبة الزائدة / قولبة الحقن بمساعدة الغاز |

| في الختام، يعد اختيار المادة البلاستيكية المناسبة لمعدات الصيد بالحقن أمرًا بالغ الأهمية لضمان متانة وأداء المنتج النهائي. من خلال النظر في عوامل مثل نوع أدوات الصيد التي يتم إنتاجها، والخصائص المطلوبة للمنتج النهائي، وعملية التصنيع، يمكن للمصنعين اختيار مادة بلاستيكية تلبي هذه المتطلبات وتنتج أدوات صيد عالية الجودة. من خلال اختيار المواد البلاستيكية بعناية لأدوات صيد الأسماك بالحقن، يمكن للمصنعين ضمان نجاح منتجاتهم وتلبية احتياجات عملائهم. | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

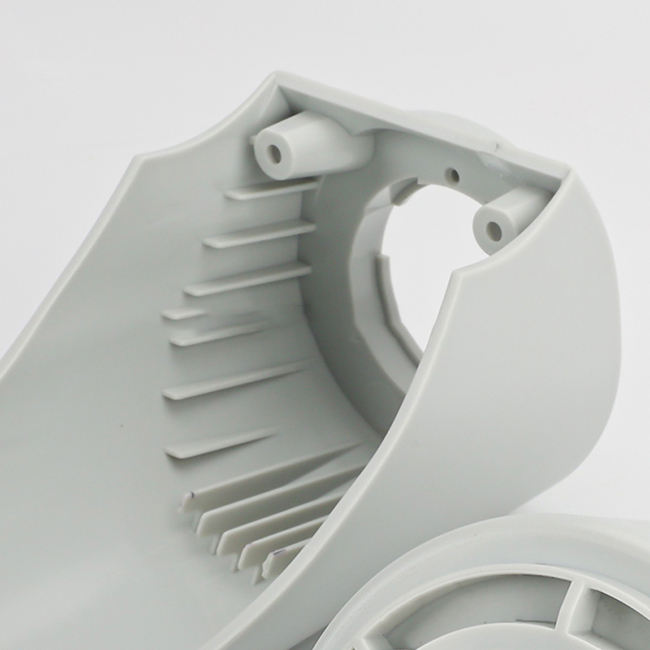

One of the most important factors to consider when choosing a plastic material for injection molding fishing tackle is the type of fishing tackle being produced. Different types of fishing tackle, such as lures, hooks, and bobbers, require different properties in order to perform effectively. For example, lures need to be lightweight and buoyant, while hooks need to be strong and durable. By understanding the specific requirements of the fishing tackle being produced, manufacturers can choose a plastic material that will meet these requirements and ensure the quality of the final product.

In addition to the type of fishing tackle being produced, manufacturers must also consider the desired properties of the final product when selecting a plastic material for injection molding. Properties such as strength, flexibility, and resistance to corrosion are important factors to consider when choosing a plastic material for fishing tackle. For example, if a manufacturer is producing fishing hooks, they may choose a plastic material that is strong and resistant to corrosion in order to ensure the durability of the final product. By considering the desired properties of the final product, manufacturers can choose a plastic material that will meet these requirements and ensure the quality of the final product.

Another important factor to consider when choosing a plastic material for injection molding fishing tackle is the manufacturing process. Different plastic materials have different properties that can affect the injection molding process, such as melt flow rate, shrinkage, and cooling time. By understanding how these properties will impact the manufacturing process, manufacturers can choose a plastic material that will be easy to work with and produce high-quality fishing tackle. Additionally, manufacturers must consider the cost of the plastic material when selecting a material for injection molding fishing tackle. Some plastic materials may be more expensive than others, so manufacturers must balance the desired properties of the final product with the cost of the material in order to produce fishing tackle that is both high-quality and cost-effective.

In conclusion, choosing the right plastic material for injection molding fishing tackle is crucial to ensure the durability and performance of the final product. By considering factors such as the type of fishing tackle being produced, the desired properties of the final product, and the manufacturing process, manufacturers can choose a plastic material that will meet these requirements and produce high-quality fishing tackle. By carefully selecting a plastic material for injection molding fishing tackle, manufacturers can ensure the success of their products and meet the needs of their customers.