Table of Contents

Advantages of Using Injection Molding Machines for Plastic Cup Production

Injection molding machines have revolutionized the way plastic cups are produced in the manufacturing industry. These machines offer a wide range of advantages that make them the preferred choice for many companies looking to mass-produce plastic cups efficiently and cost-effectively.

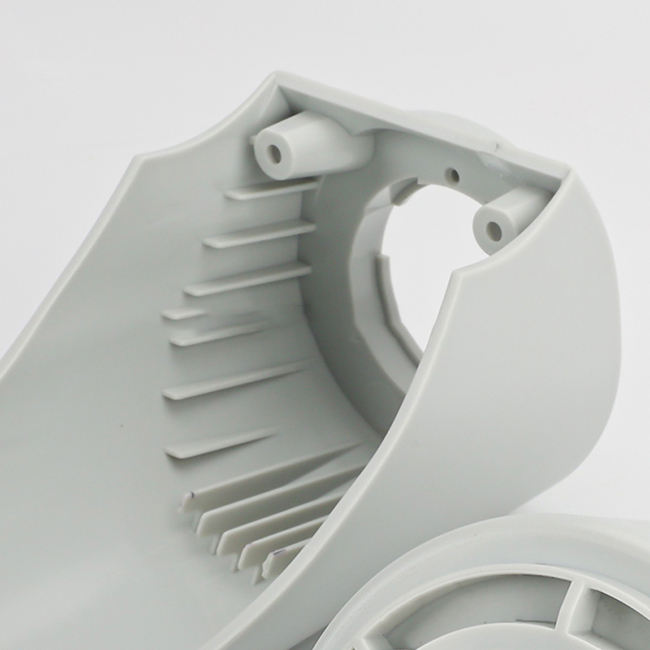

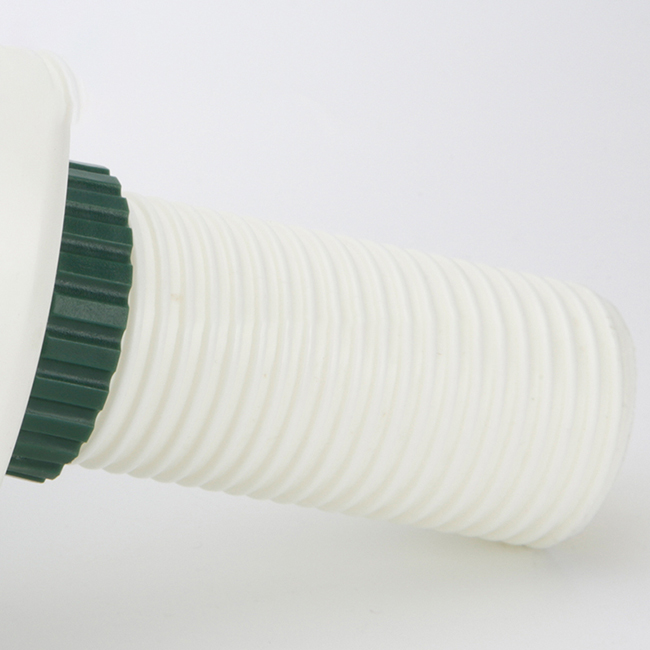

One of the key advantages of using injection molding machines for plastic cup production is the high level of precision and consistency they offer. These machines are capable of producing identical cups with minimal variation in size, shape, and thickness. This level of precision is crucial for ensuring that each cup meets the required quality standards and specifications.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Furthermore, injection molding machines are highly efficient and can produce a large number of cups in a relatively short amount of time. This makes them ideal for companies looking to meet high production demands and deadlines. The speed and efficiency of these machines also help reduce production costs, as less time and resources are required to produce each cup.

Another advantage of using injection molding machines for plastic cup production is the versatility they offer in terms of design and customization. These machines can easily accommodate changes in cup design, size, and color, allowing companies to quickly adapt to changing market trends and customer preferences. This flexibility is essential for staying competitive in the fast-paced consumer goods industry.

In addition to their precision, efficiency, and versatility, injection molding machines are also known for their durability and reliability. These machines are built to withstand the rigors of continuous use and can operate for long periods without experiencing significant downtime or maintenance issues. This reliability is crucial for ensuring uninterrupted production and meeting customer demands.

Furthermore, injection molding machines are environmentally friendly compared to other manufacturing processes. These machines produce minimal waste and can be easily recycled, making them a sustainable choice for companies looking to reduce their environmental impact. By using injection molding machines for plastic cup production, companies can minimize their carbon footprint and contribute to a cleaner, greener planet.

Overall, the advantages of using injection molding machines for plastic cup production are clear. These machines offer precision, efficiency, versatility, durability, and sustainability, making them the ideal choice for companies looking to produce high-quality cups in large quantities. By investing in injection molding machines, companies can streamline their production process, reduce costs, and stay ahead of the competition in the ever-evolving consumer goods industry.

Common Challenges and Solutions in Operating Injection Molding Machines for Plastic Cup Manufacturing

Injection molding machines are a crucial component in the manufacturing process of plastic cups. These machines are responsible for shaping molten plastic into the desired cup shape through a process known as injection molding. While injection molding machines are efficient and effective, there are common challenges that operators may face during the operation of these machines. In this article, we will explore some of these challenges and provide solutions to help operators overcome them.

One common challenge in operating injection molding machines for plastic cup manufacturing is the occurrence of defects in the final product. Defects such as warping, sink marks, and flash can occur due to a variety of factors, including improper mold design, inadequate cooling time, or incorrect machine settings. To address this challenge, operators should carefully inspect the mold design, adjust cooling times as needed, and ensure that machine settings are optimized for the specific plastic material being used.

Another challenge that operators may encounter is the issue of machine downtime. Downtime can occur due to a variety of reasons, such as equipment malfunctions, material shortages, or human error. To minimize downtime, operators should conduct regular maintenance checks on the injection molding machine, keep an inventory of spare parts on hand, and provide training to operators to prevent human error.

In addition to defects and downtime, another common challenge in operating injection molding machines is the issue of material waste. Material waste can occur due to overfilling of molds, improper material handling, or inefficient machine settings. To reduce material waste, operators should carefully monitor the amount of material being used, implement proper material handling procedures, and optimize machine settings to minimize excess material usage.

Furthermore, operators may also face challenges related to quality control in the production of plastic cups. Ensuring consistent quality in the final product is essential for meeting customer expectations and maintaining a positive reputation in the market. To address this challenge, operators should implement quality control measures such as regular inspections, testing samples of finished products, and maintaining accurate records of production data.

In conclusion, operating injection molding machines for plastic cup manufacturing can present various challenges for operators. However, by implementing the solutions mentioned above, operators can overcome these challenges and ensure a smooth and efficient production process. By carefully monitoring machine settings, conducting regular maintenance checks, and implementing quality control measures, operators can produce high-quality plastic cups that meet customer expectations and adhere to industry standards. Ultimately, by addressing these common challenges, operators can optimize the operation of injection molding machines and achieve success in the production of plastic cups.