Have you heard of SA ingredients?

SA (SAN–styrene-acrylonitrile copolymer/super glue)

SA (SAN–styrene-acrylonitrile copolymer/super glue)

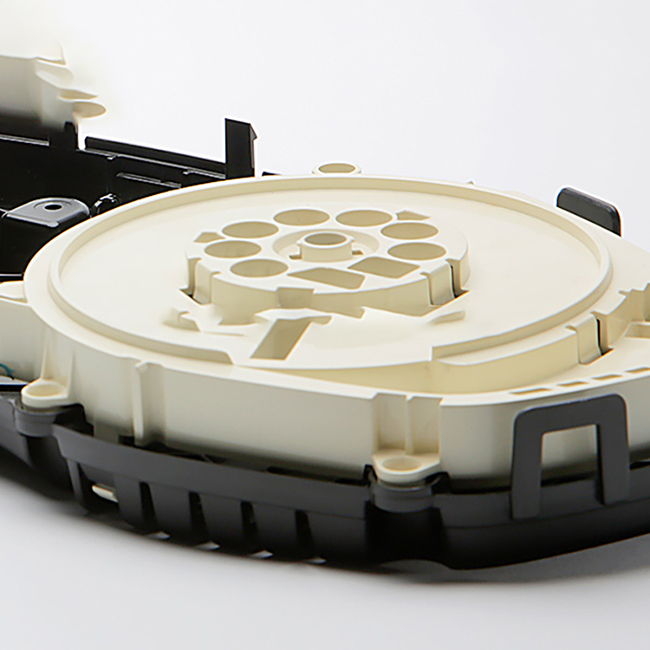

Designing injection molded plastic parts involves several key considerations to ensure successful manufacturing and optimal performance of the final product. Here are some important aspects to keep in mind: 1.Part Geometry: The geometry of the part should be carefully designed to facilitate the injection molding process. This includes minimizing the use of undercuts, sharp corners,…

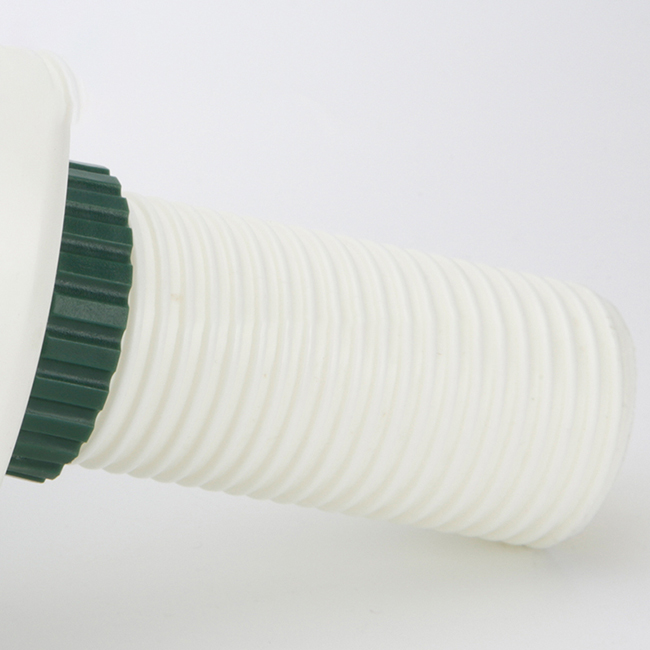

Advantages of Using Injection Molding Machines for Plastic Cup Production Injection molding machines have revolutionized the way plastic cups are produced in the manufacturing industry. These machines offer a wide range of advantages that make them the preferred choice for many companies looking to mass-produce plastic cups efficiently and cost-effectively. One of the key advantages…

Advantages of Using HDPE Injection Molding for Plastic Products High-Density Polyethylene (HDPE) injection molding is a popular method for producing a wide range of plastic products. This process involves melting plastic pellets and injecting them into a mold to create a specific shape. HDPE is a versatile material that offers many advantages for manufacturers looking…

Benefits of Using Plastic Injection Molding Machine Boxes for Packaging Plastic injection molding machine boxes have become increasingly popular in the packaging industry due to their numerous benefits. These boxes are made using a process called plastic injection molding, which involves melting plastic pellets and injecting them into a mold to create a specific shape….

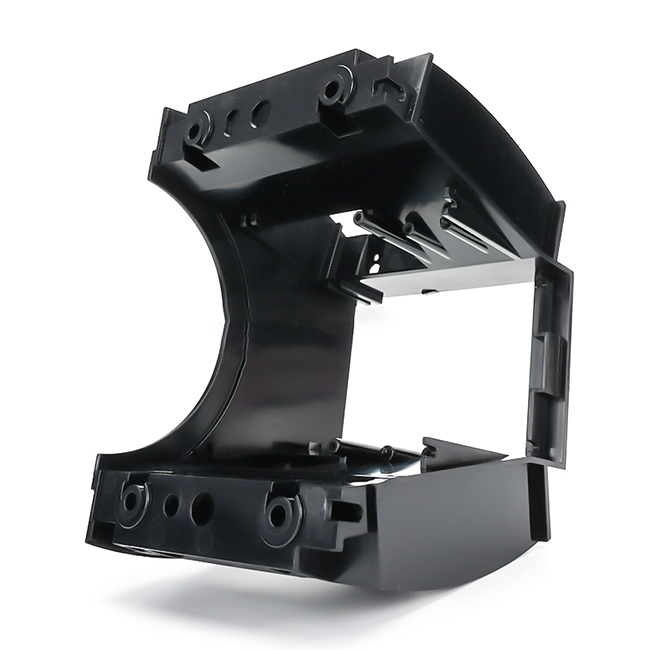

Benefits of Using ABS Plastic in Automotive Injection Molding Automotive injection molding is a widely used manufacturing process in the automotive industry. It involves injecting molten material into a mold cavity, where it cools and solidifies to form the desired part. One of the most commonly used materials in automotive injection molding is ABS plastic….

Benefits of Using a 450 Ton Plastic Injection Molding Machine Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process allows for the production of a wide range of plastic parts and products with high precision and efficiency. One key factor in the success…

Benefits of Using Aluminum Molds in Plastic Injection Molding Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. The plastic material then cools and solidifies, taking on the shape of the mold cavity. This process is used to produce a wide range of plastic products,…

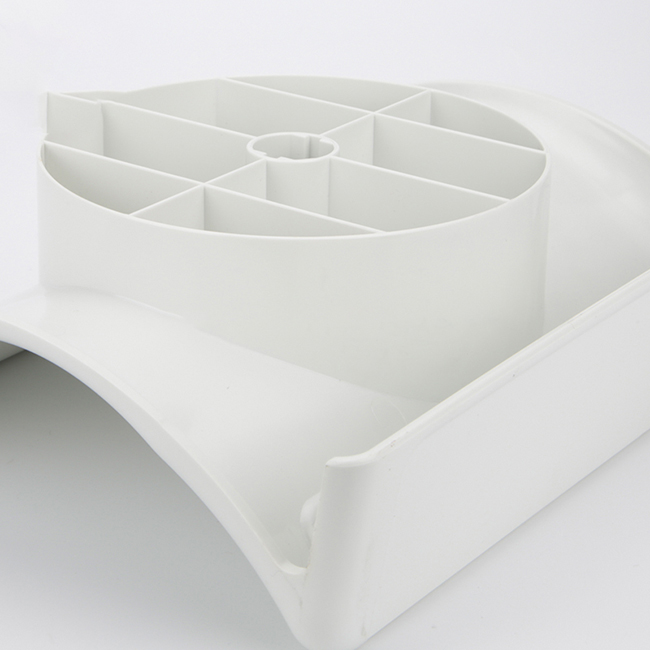

Benefits of Using Plastic Lunch Box Injection Molding Technology Plastic lunch box injection molding technology has revolutionized the way lunch boxes are manufactured. This innovative process involves injecting molten plastic into a mold to create a lunch box with precise dimensions and intricate designs. There are several benefits to using plastic lunch box injection molding…

Benefits of Using ABS Material for Injection Molding Parts ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic polymer that is widely used in injection molding processes. It offers a range of benefits that make it an ideal material for producing high-quality parts with excellent mechanical properties. In this article, we will explore the advantages of…

Benefits of Double Color Injection Molding in Plastic Manufacturing Double color injection molding is a process that involves injecting two different colors of plastic into a mold to create a single part. This technique is commonly used in the manufacturing industry to produce products with unique color combinations and designs. There are several benefits to…

Advantages of Using Haitian Plastic Injection Blow Molding in Manufacturing Processes Plastic injection blow molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create a desired shape. Haitian plastic injection blow molding is a specific type of injection blow molding that offers several advantages for manufacturers. In this…