Benefits of Double Color Injection Molding in Plastic Manufacturing

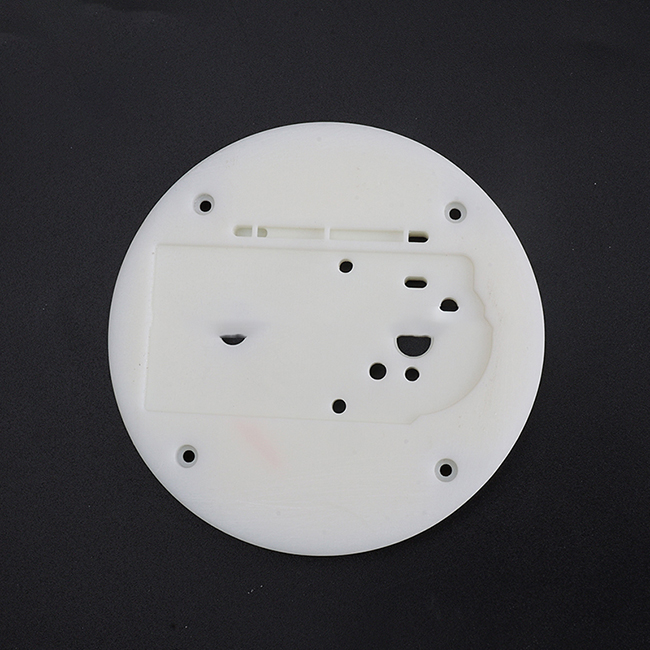

Double color injection molding is a process that involves injecting two different colors of plastic into a mold to create a single part. This technique is commonly used in the manufacturing industry to produce products with unique color combinations and designs. There are several benefits to using double color injection molding in plastic manufacturing, including increased design flexibility, improved product aesthetics, and reduced production costs.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

One of the main advantages of double color injection molding is the increased design flexibility it offers. By using two different colors of plastic, manufacturers can create intricate patterns, logos, and designs that would be difficult or impossible to achieve with traditional molding techniques. This allows for greater customization and personalization of products, making them more appealing to consumers.

In addition to enhanced design capabilities, double color injection molding also improves the overall aesthetics of the final product. By using two colors of plastic, manufacturers can create parts with a more visually appealing appearance, making them stand out from competitors. This can help to attract customers and increase sales, as consumers are often drawn to products that are unique and eye-catching.

Another benefit of double color injection molding is the potential for cost savings. While the initial investment in equipment and training may be higher than traditional molding methods, the ability to create complex designs and patterns in a single step can reduce production time and labor costs. This can result in overall savings for manufacturers, making double color injection molding a cost-effective option for producing high-quality plastic parts.

Furthermore, double color injection molding can also improve the durability and longevity of plastic products. By using two different colors of plastic, manufacturers can create parts that are more resistant to wear and tear, as the two materials can complement each other’s strengths and weaknesses. This can result in products that are more durable and long-lasting, reducing the need for frequent replacements and repairs.

Overall, double color injection molding offers a range of benefits for plastic manufacturers looking to create unique, high-quality products. From increased design flexibility and improved aesthetics to cost savings and enhanced durability, this technique can help companies stand out in a competitive market and attract more customers. By investing in double color injection molding technology, manufacturers can take their plastic manufacturing capabilities to the next level and produce innovative products that meet the needs and preferences of today’s consumers.