Table of Contents

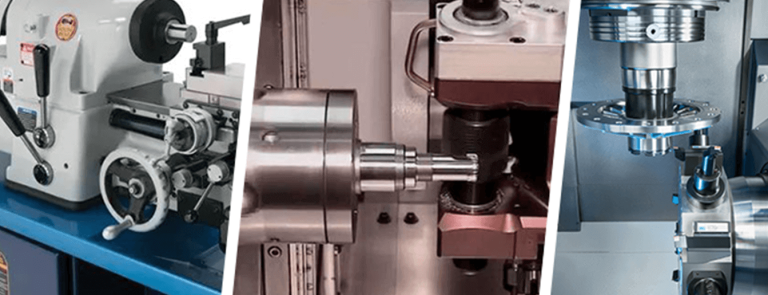

CNC Machining:

- Process: CNC machining involves using pre-programmed computer software to control machining tools (such as mills, lathes, or routers) that remove material from a solid block, creating a desired shape.

- Accuracy: CNC machines are highly accurate, capable of achieving tolerances within microns, which is essential for precise engineering and manufacturing applications.

- Versatility: They can work with a wide range of materials, including metals (aluminum, steel, brass, etc.), plastics, wood, composites, and more.

- Types of Operations: CNC machining encompasses operations like milling, turning, drilling, grinding, and more, allowing for complex geometries and features.

Casting:

- Process: Casting involves pouring molten material into a mold cavity and allowing it to solidify. Once solidified, the mold is removed to reveal the finished casting.

- Types of Casting:

- Sand Casting: Uses a mold made from sand to create metal castings.

- Die Casting: Uses a mold or die to produce intricate parts with high dimensional accuracy.

- Investment Casting: Uses a wax pattern surrounded by ceramic material to create precise metal parts.

- Materials: Commonly used materials for casting include various metals (aluminum, steel, iron, etc.) and plastics.

CNC Machining after Casting:

- Purpose: CNC machining is often used after casting to achieve tighter tolerances, improve surface finish, add features like holes or threads, and remove excess material.

- Benefits:

- Dimensional Accuracy: Ensures that cast parts meet exact specifications.

- Surface Finish: Provides a smoother surface or specific textures as required.

- Complex Geometries: Allows for the creation of intricate designs and complex shapes that casting alone may not achieve.

- Applications: Widely used in industries such as aerospace, automotive, medical equipment, and consumer goods where high precision and quality are critical.

Combined Applications and Industries:

- Aerospace: Engine components, structural parts, and airframe components often undergo both casting and CNC machining for high strength and precision.

- Automotive: Transmission housings, engine blocks, and suspension components are frequently produced using casting and machined to precise specifications.

- General Manufacturing: From industrial machinery to consumer electronics, the combination of casting and CNC machining offers versatile solutions for various applications.

Future Trends:

- Automation: Increasing use of robotics and automation in both casting and CNC machining processes to enhance productivity and reduce costs.

- Advanced Materials: Development of new materials and alloys that can be efficiently processed through casting and CNC machining.

- Digital Integration: Integration of CAD/CAM software with CNC machines to streamline design, manufacturing, and quality control processes.