Table of Contents

Post-Processing Techniques

- Trimming: Excess material, such as sprues and runners, is removed after the part is ejected from the mold.

- Painting and Coating: ABS parts can be painted or coated to improve appearance and add additional protection. Pre-treatment may be required to ensure good adhesion.

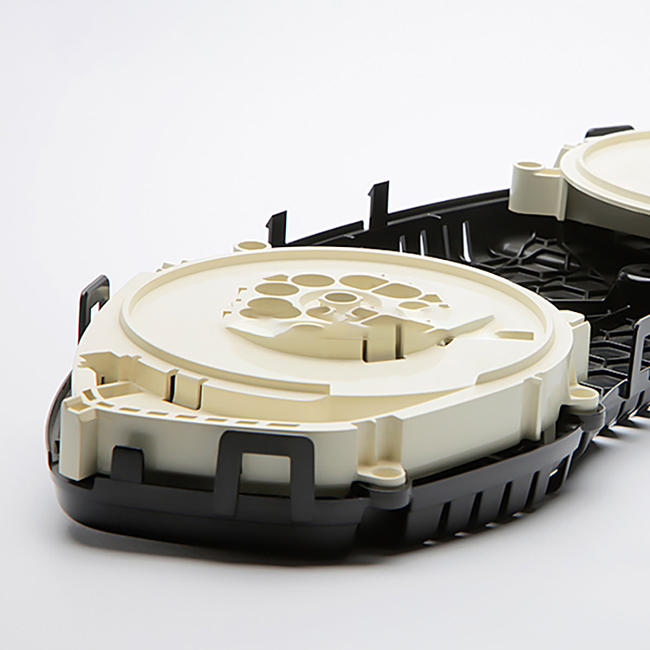

- Assembly: In cases where parts are part of an assembly, additional steps like ultrasonic welding, adhesive bonding, or mechanical fastening may be used.

- Surface Treatments: Techniques like chrome plating or texturing can be applied to enhance the appearance or functionality of the ABS parts.

Environmental Considerations

- Recycling: ABS is recyclable and can be processed into new materials. The recycling process involves grinding used ABS parts into pellets and then reprocessing them into new parts.

- Biodegradability: ABS is not biodegradable. However, efforts are being made to develop more sustainable alternatives and improve recycling processes.

Applications and Innovations

- Medical Devices: ABS is used in medical applications where strength and cleanliness are critical. Innovations in the field include creating intricate parts for diagnostic devices and equipment housings.

- Consumer Products: Innovations include customizable and ergonomic designs for personal gadgets and home appliances.

- 3D Printing: ABS is a popular material for 3D printing due to its ease of use and strong mechanical properties, enabling rapid prototyping and low-volume production.