- Search for Specialized Manufacturers:

- Look for manufacturers that specifically mention stainless steel CNC machining and casting capabilities. This specialization ensures they have the expertise and equipment necessary for your requirements.

- Evaluate Experience and Capabilities:

- Check if the manufacturer has experience with stainless steel materials. Stainless steel machining requires specific techniques due to its hardness and properties, so expertise in this area is crucial.

- Determine if they offer casting services alongside CNC machining, as this might be advantageous depending on your part’s complexity and design.

- Quality Assurance and Certifications:

- Verify the manufacturer’s quality standards and certifications. ISO 9001 certification, for example, ensures that the manufacturer has established quality management systems.

- Ask about their inspection processes and quality control measures to ensure they deliver parts that meet your specifications consistently.

- Request Samples and References:

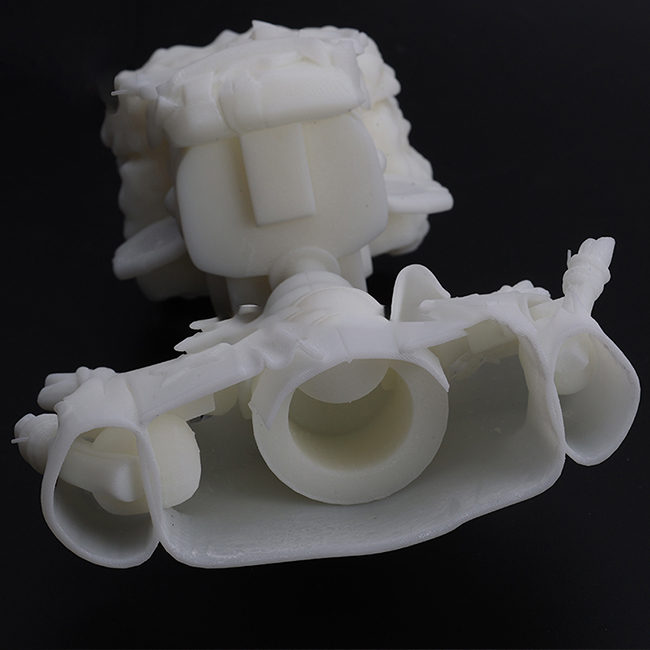

- Ask for samples of stainless steel CNC machined parts they have produced. This allows you to assess their machining quality, surface finish, and dimensional accuracy.

- Request references or case studies from previous projects involving stainless steel parts to gauge customer satisfaction and reliability.

- Communication and Collaboration:

- Communication is key to ensuring your needs are understood and met. Assess their responsiveness and willingness to collaborate throughout the manufacturing process.

- Discuss any specific requirements you have for your parts and ensure they can accommodate customizations or modifications if needed.