Table of Contents

Avantages de l’utilisation du moulage par injection plastique pour la fabrication

Nom du produit

| OEM | Moulage par injection plastique Pièces Formats de dessin |

| 2D(PDF/CAO) et 3D(STP/STEP) | Défis et solutions courants dans les opérations de moulage par injection plastique |

En conclusion, les opérations de moulage par injection plastique sont confrontées à une variété de défis qui nécessitent une planification minutieuse et une gestion proactive. En abordant des problèmes tels que la qualité des pièces, les coûts d’outillage, la sécurité des travailleurs et l’impact environnemental, les fabricants peuvent optimiser leurs processus et obtenir un succès à long terme. En mettant en œuvre les meilleures pratiques et en tirant parti de solutions innovantes, les opérations de moulage par injection de plastique peuvent surmonter les défis et prospérer dans le paysage manufacturier concurrentiel d’aujourd’hui.

Common Challenges and Solutions in Plastic Injection Molding Operations

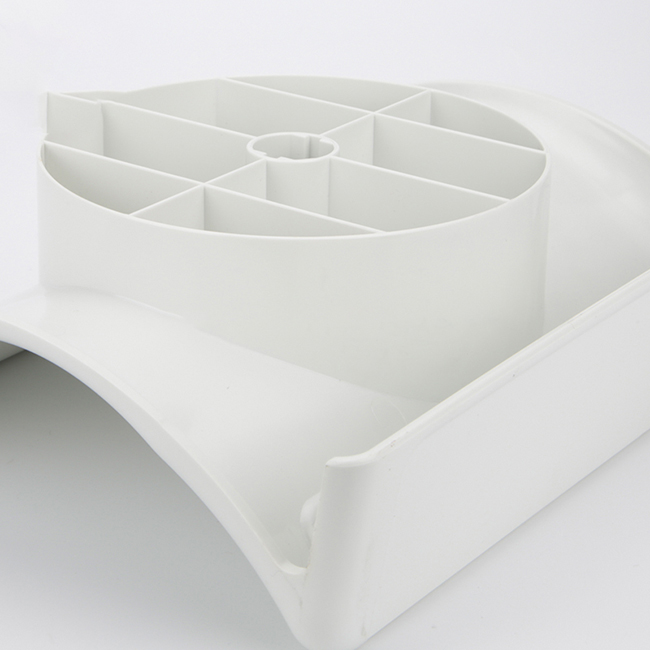

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is used to produce a wide range of plastic products, from small components to large parts. While plastic injection molding offers many benefits, such as high production efficiency and cost-effectiveness, it also presents several challenges that manufacturers must address to ensure successful operations.

One common challenge in plastic injection molding operations is achieving consistent part quality. Variations in material properties, mold design, and processing conditions can lead to defects such as warping, sink marks, and flash. To address this challenge, manufacturers must carefully control and monitor key process parameters, such as injection pressure, temperature, and cooling time. Implementing a robust quality control system that includes regular inspections and testing can help identify and correct issues before they affect part quality.

Another challenge in plastic injection molding is managing tooling costs. The molds used in injection molding are typically made of steel or aluminum and can be expensive to design and manufacture. Additionally, molds can wear out over time, leading to increased maintenance and replacement costs. To mitigate tooling costs, manufacturers can explore options such as using interchangeable inserts or implementing a preventive maintenance program to extend the life of the molds. Working closely with tooling suppliers to optimize mold design and material selection can also help reduce costs and improve overall efficiency.

One of the most critical challenges in plastic injection molding operations is ensuring worker safety. The high temperatures and pressures involved in the injection molding process can pose significant risks to operators if proper safety measures are not in place. To protect workers, manufacturers must provide comprehensive training on safe operating procedures, personal protective equipment, and emergency response protocols. Regular safety audits and inspections can help identify potential hazards and ensure compliance with industry regulations.

In addition to these challenges, plastic injection molding operations must also contend with environmental concerns. The use of plastic materials in manufacturing has come under scrutiny due to its impact on the environment, particularly in terms of waste generation and resource consumption. To address these concerns, manufacturers can explore sustainable alternatives, such as biodegradable or recycled plastics, and implement recycling programs to reduce waste. Investing in energy-efficient equipment and processes can also help minimize the environmental footprint of plastic injection molding operations.

In conclusion, plastic injection molding operations face a variety of challenges that require careful planning and proactive management. By addressing issues such as part quality, tooling costs, worker safety, and environmental impact, manufacturers can optimize their processes and achieve long-term success. By implementing best practices and leveraging innovative solutions, plastic injection molding operations can overcome challenges and thrive in today’s competitive manufacturing landscape.