Avantages de l’utilisation de pièces moulées par injection plastique ABS, PP, PC et PA66 dans la fabrication

Nom du produit

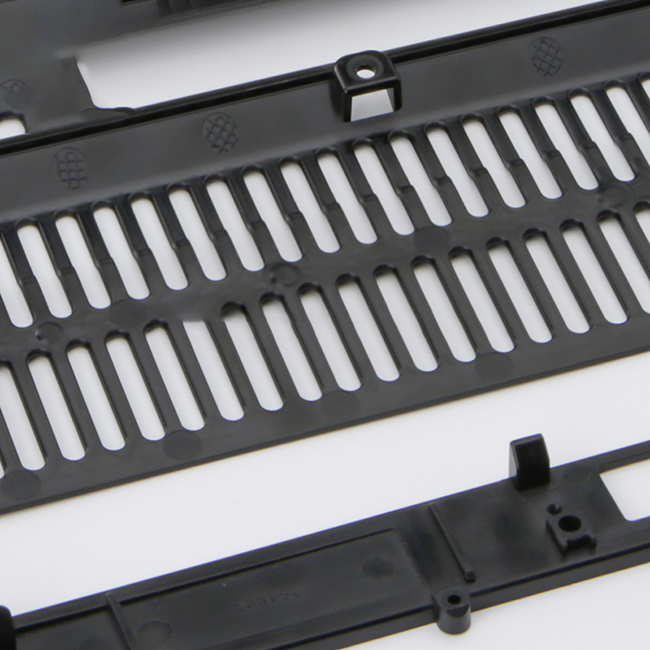

| Pièces de moulage par injection plastique OEM | Technologie |

| Mousse / Injection ordinaire / Moulage de mousse structurelle / Surmoulage / Moulage par injection assisté par gaz | Finition de surface |

| Finition de polissage/impression Slik/finition texturée/peinture en caoutchouc/finition brillante/peinture/écran Slik/tampographie/revêtement EMI/placage électronique/marquage laser/Etc. | De plus, les pièces moulées par injection plastique ABS, PP, PC et PA66 sont hautement personnalisables. Les fabricants peuvent facilement ajuster la composition des matériaux, la couleur et la finition de surface de ces pièces pour répondre à des exigences de conception spécifiques. Cette flexibilité permet la production de produits uniques et innovants qui se démarquent sur le marché.

Dans l’ensemble, les pièces moulées par injection plastique ABS, PP, PC et PA66 offrent un large éventail d’avantages pour les fabricants cherchant à produire des produits de haute qualité à moindre coût. -des composants efficaces. De leurs excellentes propriétés mécaniques à leurs options de personnalisation, ces matériaux constituent un choix polyvalent et fiable pour diverses industries. En tirant parti des avantages des pièces moulées par injection plastique ABS, PP, PC et PA66, les fabricants peuvent rationaliser leurs processus de production et fournir des produits de qualité supérieure à leurs clients. |

PP, or Polypropylene, is another popular material used in plastic injection molding. It is a lightweight and flexible thermoplastic that is resistant to chemicals and moisture. PP plastic injection molding parts are commonly used in the packaging, automotive, and medical industries due to their excellent chemical resistance and low moisture absorption properties.

PC, or Polycarbonate, is a transparent thermoplastic that is known for its high impact resistance and optical clarity. It is commonly used in the automotive, aerospace, and electronics industries for applications that require high strength and transparency. PC plastic injection molding parts are ideal for products that need to withstand harsh environments and maintain their clarity over time.

PA66, or Polyamide 66, is a strong and durable thermoplastic that is known for its high tensile strength and heat resistance. It is commonly used in the automotive, electrical, and industrial industries for applications that require high mechanical strength and thermal stability. PA66 plastic injection molding parts are ideal for products that need to withstand high temperatures and heavy loads.

One of the main benefits of using ABS, PP, PC, and PA66 plastic injection molding parts is their cost-effectiveness. These materials are readily available and can be easily molded into complex shapes, reducing the need for additional machining or finishing processes. This results in lower production costs and faster lead times, making plastic injection molding an efficient manufacturing solution for a wide range of industries.

In addition to cost-effectiveness, ABS, PP, PC, and PA66 plastic injection molding parts offer excellent mechanical properties. These materials are known for their high strength, impact resistance, and durability, making them ideal for applications that require reliable and long-lasting components. Whether it’s a small electronic device or a large automotive part, ABS, PP, PC, and PA66 plastic injection molding parts can meet the demanding requirements of various industries.

Furthermore, ABS, PP, PC, and PA66 plastic injection molding parts are highly customizable. Manufacturers can easily adjust the material composition, color, and surface finish of these parts to meet specific design requirements. This flexibility allows for the production of unique and innovative products that stand out in the market.

Overall, ABS, PP, PC, and PA66 plastic injection molding parts offer a wide range of benefits for manufacturers looking to produce high-quality and cost-effective components. From their excellent mechanical properties to their customization options, these materials are a versatile and reliable choice for a variety of industries. By leveraging the advantages of ABS, PP, PC, and PA66 plastic injection molding parts, manufacturers can streamline their production processes and deliver superior products to their customers.