Avantages de l’utilisation du moulage par injection pour la production de bouchons en plastique

Finition de surface

| Finition de polissage/impression Slik/finition texturée/peinture en caoutchouc/finition brillante/peinture/écran Slik/tampographie/revêtement EMI/placage électronique/marquage laser/Etc. | Processus de production |

| Commandes-Matières Premières- Production-Contrôle Qualité -Emballage-Expédition | Livraison |

| Sac PE + carte papier/peau de papier + carton/caisse/palette de qualité exportation | De plus, le moulage par injection est un processus polyvalent qui peut s’adapter à une large gamme de matières plastiques. Différents types de plastiques peuvent être utilisés dans le processus de moulage par injection, permettant aux fabricants de sélectionner des matériaux qui répondent à des exigences spécifiques en matière de résistance, de durabilité, de flexibilité et d’autres propriétés. Cette flexibilité dans la sélection des matériaux permet aux fabricants de produire des bouchons adaptés aux besoins de leur application spécifique.

En conclusion, le moulage par injection offre de nombreux avantages pour la production de bouchons en plastique, notamment la possibilité de créer des formes complexes avec une haute précision et des volumes de production élevés. , cohérence et répétabilité, solutions rentables et polyvalence des matériaux. Ces avantages font du moulage par injection un choix privilégié pour les fabricants à la recherche de solutions efficaces et fiables pour la production de bouchons en plastique. En tirant parti des avantages du moulage par injection, les fabricants peuvent produire des bouchons de haute qualité qui répondent aux demandes de leurs clients et du marché. |

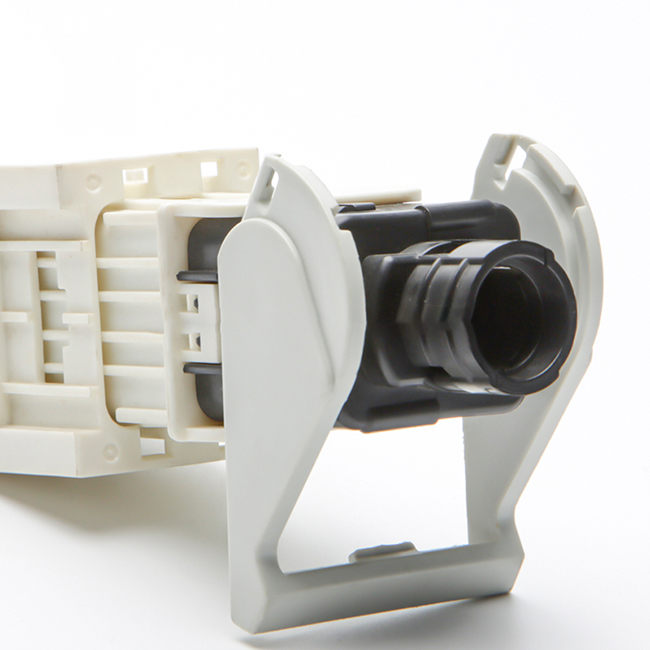

One of the key advantages of using injection molding for plastic cap production is the ability to create complex shapes and intricate designs with high precision. The mold cavity can be customized to the exact specifications of the cap, allowing for intricate details and features to be incorporated into the design. This level of precision is essential for producing caps that fit securely and function effectively on various types of containers.

Additionally, injection molding allows for high production volumes to be achieved quickly and efficiently. Once the mold is set up and the machine is running, the process can produce large quantities of caps in a relatively short amount of time. This high production rate is ideal for meeting the demands of large-scale manufacturing operations and ensuring a steady supply of caps for distribution.

Another benefit of injection molding for plastic cap production is the consistency and repeatability of the process. Each cap produced using injection molding is virtually identical to the next, ensuring uniformity in size, shape, and quality. This consistency is crucial for maintaining product integrity and brand reputation, as consumers expect caps to be uniform in appearance and performance.

Injection molding also offers cost-effective solutions for plastic cap production. The initial tooling costs for creating the mold may be higher than other manufacturing processes, but the per-unit cost of each cap is relatively low. This cost efficiency is further enhanced by the high production rates achievable with injection molding, making it a cost-effective option for producing large quantities of caps.

Furthermore, injection molding is a versatile process that can accommodate a wide range of plastic materials. Different types of plastics can be used in the injection molding process, allowing manufacturers to select materials that meet specific requirements for strength, durability, flexibility, and other properties. This flexibility in material selection enables manufacturers to produce caps that are tailored to the needs of their specific application.

In conclusion, injection molding offers numerous benefits for producing plastic caps, including the ability to create complex shapes with high precision, high production volumes, consistency and repeatability, cost-effective solutions, and material versatility. These advantages make injection molding a preferred choice for manufacturers seeking efficient and reliable solutions for plastic cap production. By leveraging the benefits of injection molding, manufacturers can produce high-quality caps that meet the demands of their customers and the market.