Table of Contents

Advantages of Using Haitian Plastic Injection Blow Molding in Manufacturing Processes

Plastic injection blow molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create a desired shape. Haitian plastic injection blow molding is a specific type of injection blow molding that offers several advantages for manufacturers. In this article, we will explore the benefits of using Haitian plastic injection blow molding in manufacturing processes.

One of the key advantages of Haitian plastic injection blow molding is its cost-effectiveness. This process allows for high production volumes at a relatively low cost, making it an attractive option for manufacturers looking to produce large quantities of plastic parts. Additionally, Haitian plastic injection blow molding can help reduce material waste, as the process is highly efficient and produces minimal scrap.

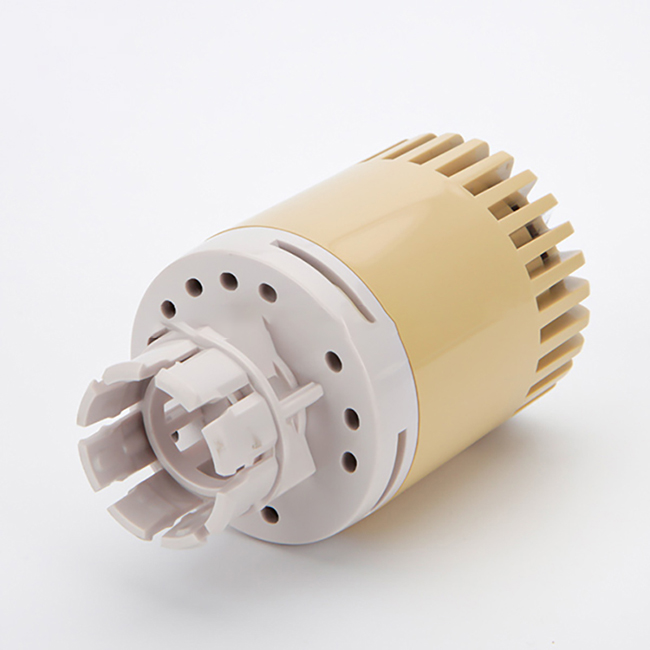

Another advantage of Haitian plastic injection blow molding is its versatility. This process can be used to create a wide range of complex shapes and sizes, making it suitable for a variety of applications. Whether you need to produce small, intricate parts or large, durable components, Haitian plastic injection blow molding can meet your manufacturing needs.

In addition to its cost-effectiveness and versatility, Haitian plastic injection blow molding offers excellent precision and consistency. The process allows for tight tolerances and high levels of accuracy, ensuring that each part produced is of the highest quality. This precision is essential for industries such as automotive, aerospace, and medical, where even the smallest deviation can have serious consequences.

Furthermore, Haitian plastic injection blow molding is a fast and efficient process. With the ability to produce large quantities of parts in a short amount of time, manufacturers can meet tight production deadlines and respond quickly to changing market demands. This speed and efficiency can give companies a competitive edge in today’s fast-paced manufacturing environment.

Additionally, Haitian plastic injection blow molding is a sustainable manufacturing option. The process can be used with a variety of recyclable materials, reducing the environmental impact of production. By choosing Haitian plastic injection blow molding, manufacturers can demonstrate their commitment to sustainability and responsible manufacturing practices.

Overall, Haitian plastic injection blow molding offers numerous advantages for manufacturers looking to produce high-quality plastic parts efficiently and cost-effectively. From its cost-effectiveness and versatility to its precision and sustainability, this process has much to offer businesses in a wide range of industries. By incorporating Haitian plastic injection blow molding into their manufacturing processes, companies can improve their production capabilities and stay ahead of the competition.

Sustainability Benefits of Implementing Haitian Plastic Injection Blow Molding Technology

Haitian plastic injection blow molding technology is a sustainable solution that offers numerous benefits for manufacturers looking to reduce their environmental impact. This innovative technology allows for the production of high-quality plastic products with minimal waste and energy consumption. By implementing Haitian plastic injection blow molding technology, companies can not only improve their bottom line but also contribute to a more sustainable future.

One of the key benefits of Haitian plastic injection blow molding technology is its ability to reduce material waste. Traditional manufacturing processes often result in a significant amount of scrap material that ends up in landfills. With injection blow molding, however, manufacturers can produce products with a high level of precision, minimizing the amount of waste generated during the production process. This not only helps to reduce the environmental impact of manufacturing but also saves companies money by reducing material costs.

In addition to reducing material waste, Haitian plastic injection blow molding technology also offers energy efficiency benefits. The process of injection blow molding requires less energy than traditional manufacturing methods, making it a more sustainable option for companies looking to reduce their carbon footprint. By using less energy during the production process, manufacturers can lower their operating costs and decrease their overall environmental impact.

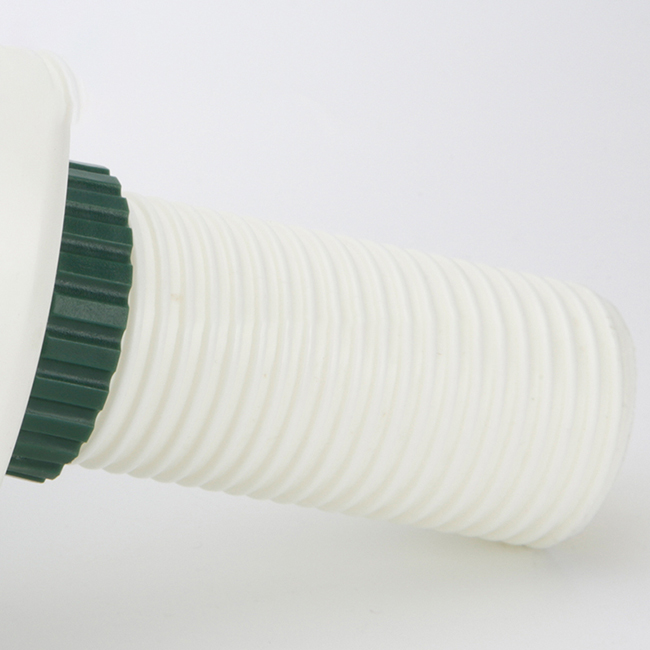

Furthermore, Haitian plastic injection blow molding technology allows for the production of lightweight and durable plastic products. This is particularly important in industries such as automotive and packaging, where lightweight materials are essential for reducing fuel consumption and transportation costs. By using injection blow molding technology, manufacturers can create products that are both strong and lightweight, helping to improve efficiency and sustainability across a wide range of industries.

Another key benefit of Haitian plastic injection blow molding technology is its versatility. This technology can be used to produce a wide variety of plastic products, from bottles and containers to automotive parts and medical devices. This versatility allows manufacturers to streamline their production processes and reduce the need for multiple manufacturing methods, further reducing waste and energy consumption.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

Overall, Haitian plastic injection blow molding technology offers a sustainable solution for manufacturers looking to improve their environmental impact. By reducing material waste, increasing energy efficiency, and creating lightweight and durable products, this technology can help companies lower their operating costs and contribute to a more sustainable future. With its versatility and cost-saving benefits, Haitian plastic injection blow molding technology is a valuable tool for companies looking to embrace sustainability in their manufacturing processes.