Benefits of Injection Blow Molding in Plastic Manufacturing

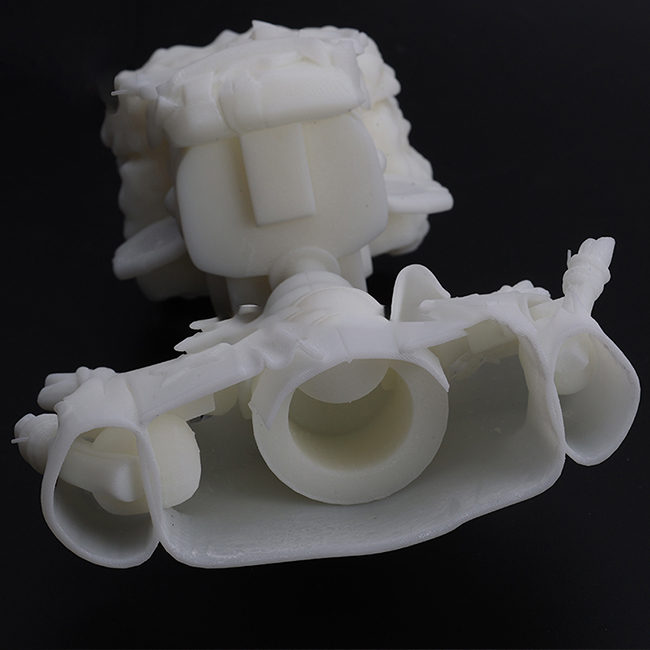

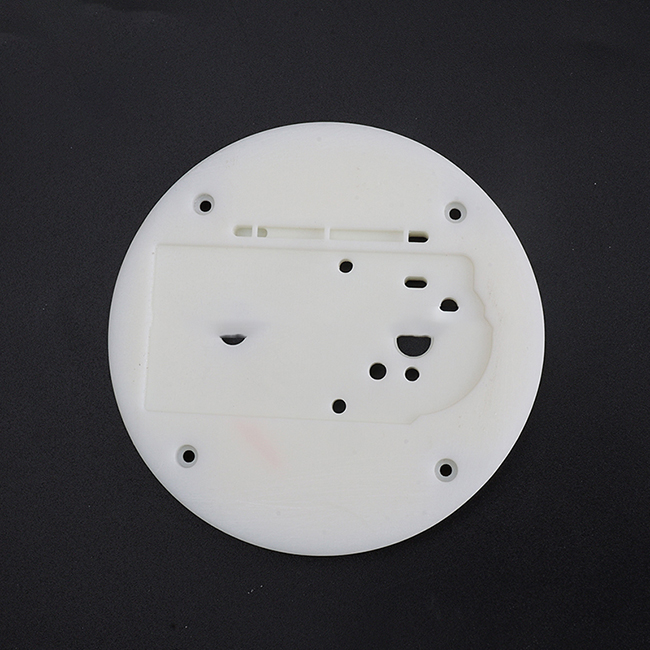

Injection blow molding is a widely used manufacturing process in the plastic industry that offers numerous benefits for producing high-quality plastic products. This process involves injecting molten plastic into a mold cavity, where it is then blown into the desired shape using compressed air. The result is a seamless, hollow plastic product that is both durable and lightweight.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

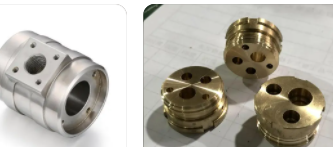

One of the key advantages of injection blow molding is its ability to produce complex shapes with high precision and consistency. This process allows for intricate details and tight tolerances to be achieved, making it ideal for manufacturing products with intricate designs or specific requirements. Additionally, injection blow molding is a cost-effective method for producing large quantities of plastic products, as it allows for fast cycle times and minimal material waste.

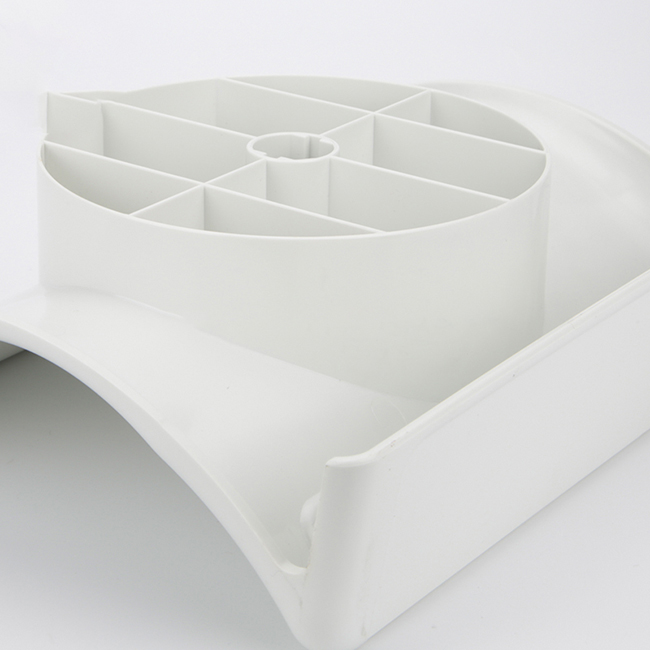

Another benefit of injection blow molding is its versatility in producing a wide range of plastic products. This process can be used to manufacture anything from small containers and bottles to larger automotive parts and medical devices. The ability to produce a variety of products with different shapes and sizes makes injection blow molding a popular choice for many industries.

In addition to its versatility, injection blow molding offers excellent surface finish and quality for plastic products. The process allows for smooth and uniform surfaces to be achieved, reducing the need for additional finishing processes. This results in a high-quality final product that meets the strict standards of many industries.

Furthermore, injection blow molding is a highly efficient process that can help reduce production costs and lead times. The ability to produce large quantities of plastic products in a short amount of time makes injection blow molding a cost-effective solution for many manufacturers. Additionally, the process requires minimal labor and maintenance, further reducing overall production costs.

One of the key advantages of injection blow molding is its ability to produce lightweight and durable plastic products. The hollow nature of the products produced through this process makes them lightweight, yet strong and durable. This makes injection blow molding an ideal choice for manufacturing products that require a high strength-to-weight ratio, such as automotive components or medical devices.

Overall, injection blow molding offers numerous benefits for plastic manufacturers looking to produce high-quality products efficiently and cost-effectively. From its ability to produce complex shapes with high precision to its versatility in producing a wide range of products, injection blow molding is a popular choice for many industries. With its excellent surface finish and quality, as well as its lightweight and durable products, injection blow molding continues to be a preferred method for plastic manufacturing.