Benefits of Using Large Clear Plastic Injection Molding Parts

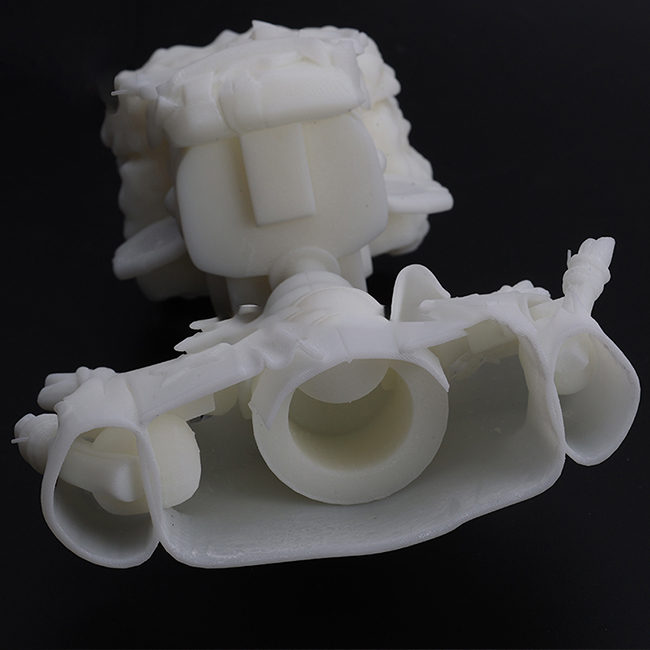

Large clear plastic injection molding parts offer a wide range of benefits for manufacturers across various industries. These parts are produced using a process that involves injecting molten plastic material into a mold cavity, which then solidifies to form the desired shape. The result is a high-quality, durable part that is both cost-effective and efficient to produce.

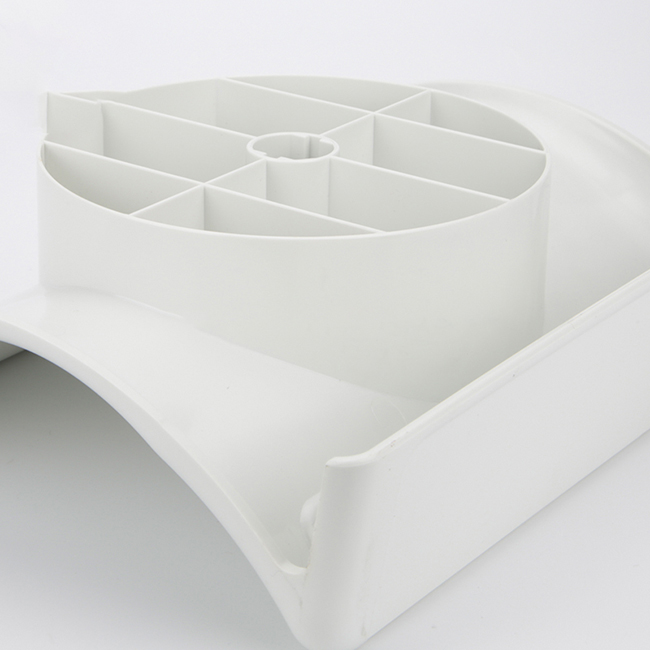

One of the key benefits of using large clear plastic injection molding parts is their versatility. These parts can be manufactured in a wide range of shapes and sizes, making them suitable for a variety of applications. Whether you need a small, intricate part or a large, complex component, plastic injection molding can accommodate your needs.

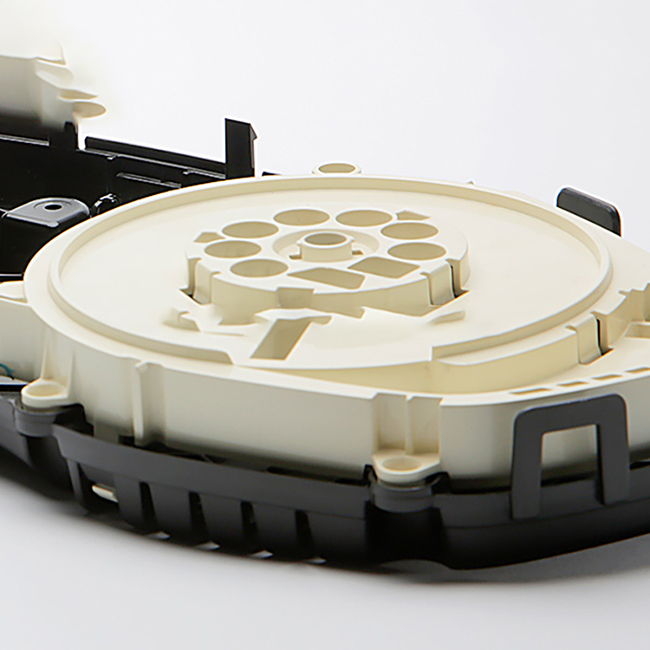

In addition to their versatility, large clear plastic injection molding parts are also known for their durability. The plastic material used in the molding process is strong and resilient, making it ideal for parts that need to withstand harsh conditions or heavy use. This durability ensures that the parts will last for a long time, reducing the need for frequent replacements and saving money in the long run.

Another benefit of using large clear plastic injection molding parts is their cost-effectiveness. The molding process is highly efficient, allowing manufacturers to produce large quantities of parts quickly and at a low cost. This efficiency translates to savings for the manufacturer, who can then pass those savings on to the consumer. Additionally, the durability of plastic injection molding parts means that they require less maintenance and replacement, further reducing costs over time.

Large clear plastic injection molding parts are also lightweight, which can be advantageous in certain applications. The lightweight nature of these parts makes them easy to transport and install, reducing labor costs and simplifying the manufacturing process. Additionally, the lightweight properties of plastic injection molding parts can help to improve the overall efficiency of a product, making it more appealing to consumers.

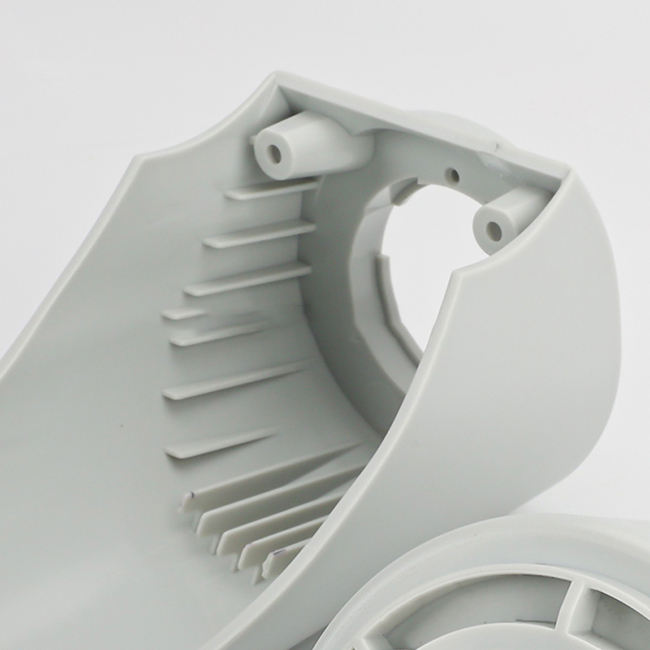

Furthermore, large clear plastic injection molding parts are highly customizable. Manufacturers can easily adjust the design and specifications of the mold to create parts that meet their exact requirements. This level of customization allows for greater flexibility in product development and can help manufacturers to create unique, innovative products that stand out in the market.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

Overall, the benefits of using large clear plastic injection molding parts are numerous. From their versatility and durability to their cost-effectiveness and customization options, these parts offer a range of advantages for manufacturers looking to produce high-quality components. By choosing plastic injection molding, manufacturers can streamline their production process, reduce costs, and create products that are both functional and visually appealing.