Table of Contents

Benefits of Using Mini Small Desktop Plastic Injection Molding Machines

Mini small desktop plastic injection molding machines are becoming increasingly popular in the manufacturing industry due to their numerous benefits. These compact machines offer a cost-effective and efficient solution for producing small plastic parts in a variety of industries. In this article, we will explore the advantages of using mini small desktop plastic injection molding machines.

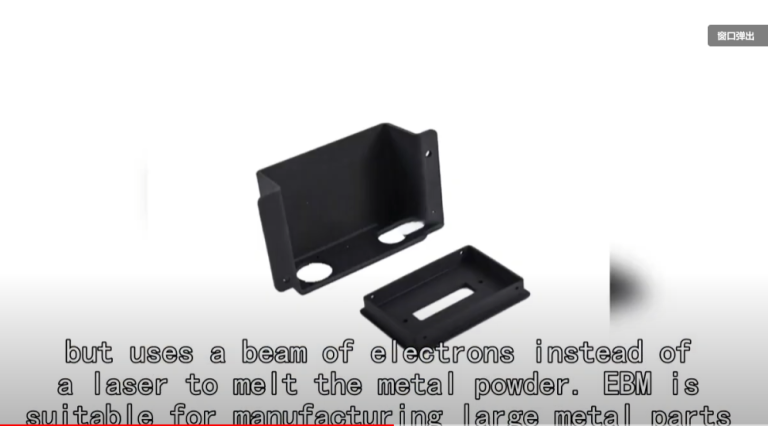

One of the key benefits of mini small desktop plastic injection molding machines is their compact size. These machines are designed to fit on a desk or workbench, making them ideal for small-scale production or prototyping. Their small footprint also makes them easy to transport and set up, allowing manufacturers to quickly switch between different production runs.

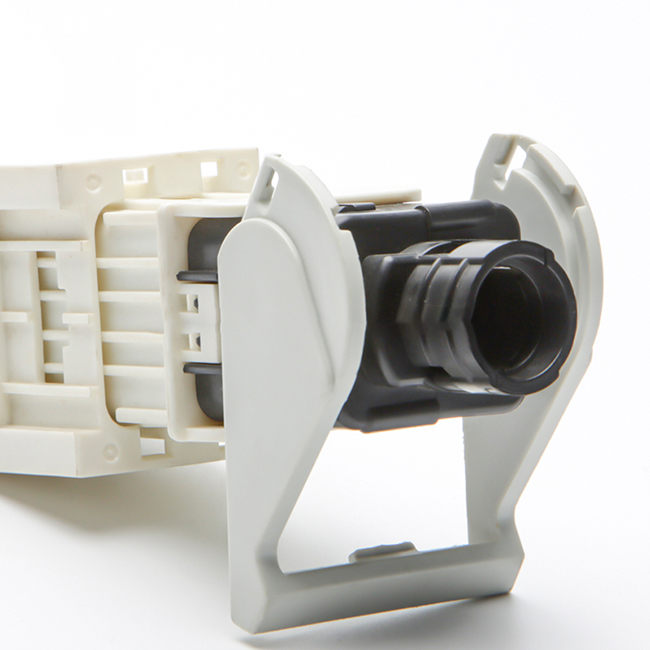

Despite their small size, mini small desktop plastic injection molding machines are capable of producing high-quality plastic parts with precision and accuracy. These machines are equipped with advanced technology and features, such as digital controls and automated processes, that ensure consistent and reliable results. This level of precision is essential for producing complex and intricate plastic parts that meet strict quality standards.

Another advantage of mini small desktop plastic injection molding machines is their cost-effectiveness. These machines are significantly cheaper than larger industrial injection molding machines, making them a more affordable option for small businesses or startups. Additionally, mini small desktop plastic injection molding machines require less energy and raw materials to operate, further reducing production costs.

Mini small desktop plastic injection molding machines also offer a faster turnaround time compared to traditional manufacturing methods. These machines can produce plastic parts in a matter of minutes, allowing manufacturers to quickly respond to changing market demands or customer requirements. This rapid production capability is essential for staying competitive in today’s fast-paced business environment.

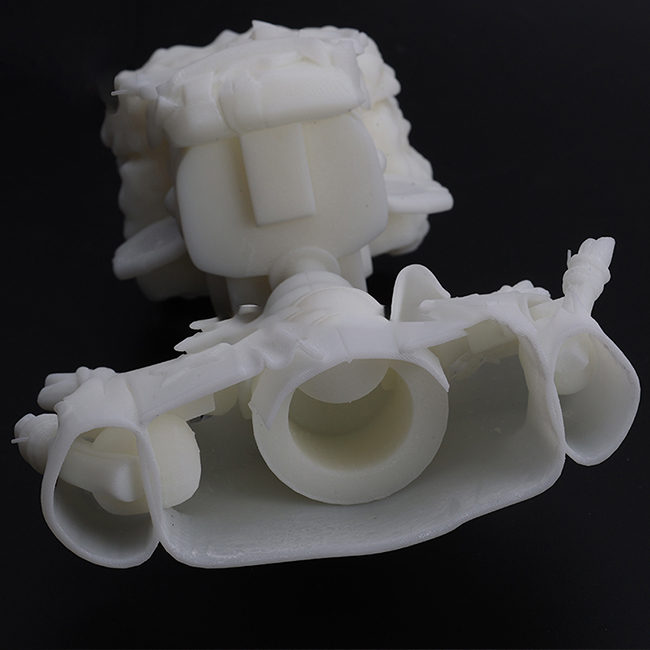

In addition to their speed and efficiency, mini small desktop plastic injection molding machines are also versatile in terms of the types of plastic materials they can process. These machines can work with a wide range of thermoplastics, including ABS, PET, and nylon, giving manufacturers the flexibility to produce a variety of plastic parts for different applications. This versatility is particularly valuable for businesses that need to produce small batches of custom or specialized plastic parts.

Furthermore, mini small desktop plastic injection molding machines are easy to operate and maintain. These machines are designed with user-friendly interfaces and intuitive controls that make them accessible to operators of all skill levels. Additionally, mini small desktop plastic injection molding machines require minimal maintenance and upkeep, reducing downtime and ensuring continuous production.

Overall, mini small desktop plastic injection molding machines offer a cost-effective, efficient, and versatile solution for producing small plastic parts. These compact machines are ideal for small businesses, startups, and manufacturers looking to streamline their production processes and increase their competitiveness in the market. With their advanced technology, precision, and ease of use, mini small desktop plastic injection molding machines are a valuable asset for any manufacturing operation.

Tips for Choosing the Right Mini Small Desktop Plastic Injection Molding Machine

Mini small desktop plastic injection molding machines are becoming increasingly popular among hobbyists, small businesses, and DIY enthusiasts. These compact machines offer a cost-effective way to produce small plastic parts in-house, without the need for expensive industrial equipment. However, with so many options available on the market, choosing the right machine can be a daunting task. In this article, we will provide some tips to help you select the best mini small desktop plastic injection molding machine for your needs.

First and foremost, it is important to consider the size and capacity of the machine. Mini small desktop plastic injection molding machines come in a range of sizes, with some capable of producing parts as small as a few millimeters in size. Before making a purchase, carefully consider the size of the parts you will be producing and choose a machine that can accommodate your needs.

Another important factor to consider is the material compatibility of the machine. While most mini small desktop plastic injection molding machines are designed to work with a wide range of thermoplastics, some may be better suited for specific materials. Make sure to check the machine’s specifications to ensure that it is compatible with the type of plastic you will be using.

In addition to size and material compatibility, it is also important to consider the machine’s features and capabilities. Some mini small desktop plastic injection molding machines come equipped with advanced features such as digital controls, automatic temperature control, and variable injection speeds. These features can help improve the quality and consistency of your parts, so be sure to choose a machine that offers the features you need.

When choosing a mini small desktop plastic injection molding machine, it is also important to consider the machine’s ease of use and maintenance requirements. Look for a machine that is user-friendly and easy to operate, with clear instructions and intuitive controls. Additionally, consider the machine’s maintenance requirements and make sure that you are able to easily access and replace any worn or damaged parts.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

Finally, it is important to consider the price of the machine. Mini small desktop plastic injection molding machines can vary widely in price, depending on their size, features, and capabilities. Before making a purchase, carefully consider your budget and choose a machine that offers the best value for your money.

In conclusion, choosing the right mini small desktop plastic injection molding machine requires careful consideration of factors such as size, material compatibility, features, ease of use, maintenance requirements, and price. By taking the time to research and compare different machines, you can find the perfect machine to meet your needs and help you produce high-quality plastic parts in-house.