Inhoudsopgave

Applications

- Prototyping

- Rapid Prototyping: CNC resin casting is frequently used in rapid prototyping to create detailed and accurate models of parts and products. The CNC machine can precisely carve prototypes from a variety of materials, which are then used to cast resin components.

- Functional Prototypes: For testing the design and functionality of parts before committing to full-scale production, this method allows for quick adjustments and iterations.

- Custom Parts and Small Runs

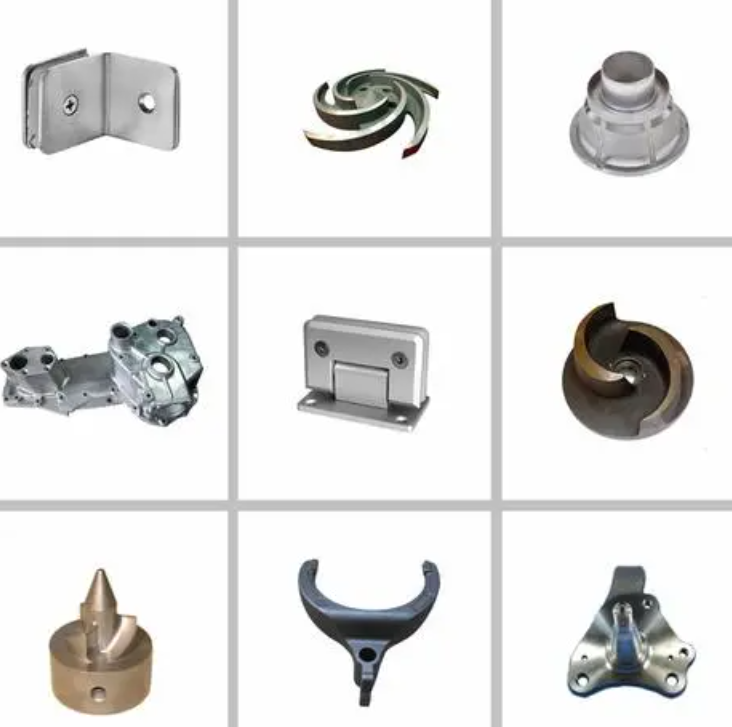

- Custom Designs: Ideal for creating unique, custom parts that require high precision. This is useful in industries like automotive, aerospace, and consumer goods, where custom components are needed.

- Small Batch Production: Resin casting allows for the production of small quantities of parts without the high costs associated with metal molds and mass production techniques.

- Art and Design

- Artistic Creations: Artists and designers use CNC resin casting to produce detailed sculptures, ornaments, and other artistic pieces. The ability to precisely control the mold shape ensures high-quality, intricate designs.

- Jewelry and Accessories

- Detailed Casting: For jewelry and other accessories, CNC machines create intricate molds that result in highly detailed and accurate resin castings. This allows for the creation of complex patterns and designs that might be difficult to achieve with traditional casting methods.

Advantages

- Precision and Accuracy

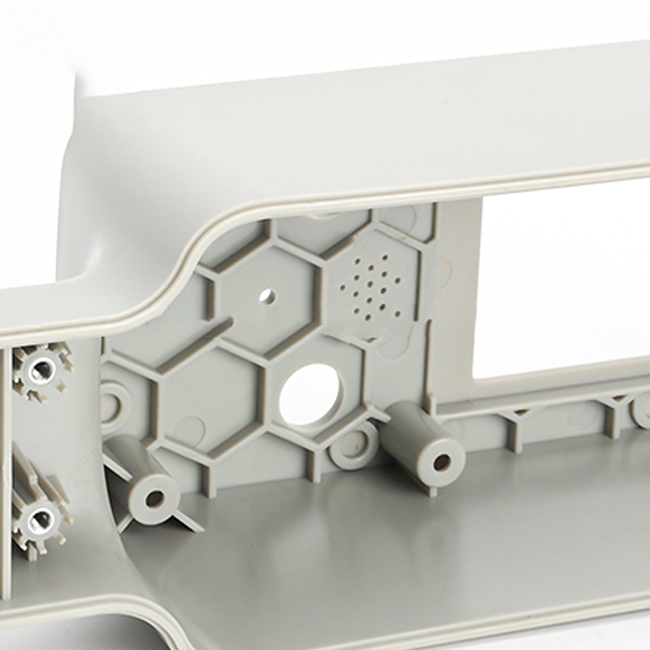

- High Detail: CNC machining provides exceptional accuracy, which translates into high-quality molds with fine details. This precision ensures that the resin castings are true to the original design specifications.

- Complex Geometries

- Intricate Designs: CNC machines can handle complex shapes and geometries that are challenging for other casting methods. This capability allows for the creation of detailed and elaborate parts.

- Versatility

- Material Flexibility: Different types of resins can be used depending on the requirements of the application, such as high-impact resins for durability or flexible resins for elasticity.

- Cost-Effective for Small Batches

- Reduced Tooling Costs: Unlike metal molds, which are expensive to create, CNC-resin casting molds can be made more affordably. This makes it an economical choice for small production runs or custom pieces.

- Quick Turnaround

- Fast Production: The combination of CNC machining and resin casting allows for rapid production and turnaround times. This is especially beneficial for industries requiring quick prototyping or small-batch production.

- Low Waste

- Efficient Use of Materials: CNC machining is precise and minimizes material waste, while resin casting is relatively efficient, making this process more environmentally friendly compared to some traditional manufacturing methods.

Summary

CNC resin casting is a powerful technique for creating detailed, high-quality parts with complex geometries. It is particularly valuable for prototyping, custom parts, art, and small production runs. The precision of CNC machining combined with the versatility and efficiency of resin casting provides numerous advantages, including cost-effectiveness, rapid turnaround, and reduced material waste.