Inhoudsopgave

Investment Casting:

- Process Overview:

- Pattern Creation: A wax or plastic pattern is created based on the final part design.

- Assembly: Multiple wax patterns are attached to a central wax sprue to form a cluster (tree).

- Coating: The wax cluster is repeatedly dipped in ceramic slurry to build a ceramic shell around it.

- Burnout: The ceramic-coated assembly is heated to melt and remove the wax, leaving a hollow ceramic mold.

- Pouring: Molten metal is poured into the mold cavity.

- Finishing: After solidification, the ceramic shell is broken away, and the final part is cleaned and finished as required.

- Advantages:

- Complex Shapes: Can produce parts with complex geometries, thin walls, and fine details.

- Surface Finish: Excellent surface finish and dimensional accuracy.

- Material Versatility: Supports a wide range of metals and alloys.

- Minimal Machining: Often requires minimal post-processing due to near-net shape casting.

- Applications:

- Aerospace: Turbine blades, engine components.

- Medical: Surgical instruments, implants.

- Automotive: Engine parts, brackets.

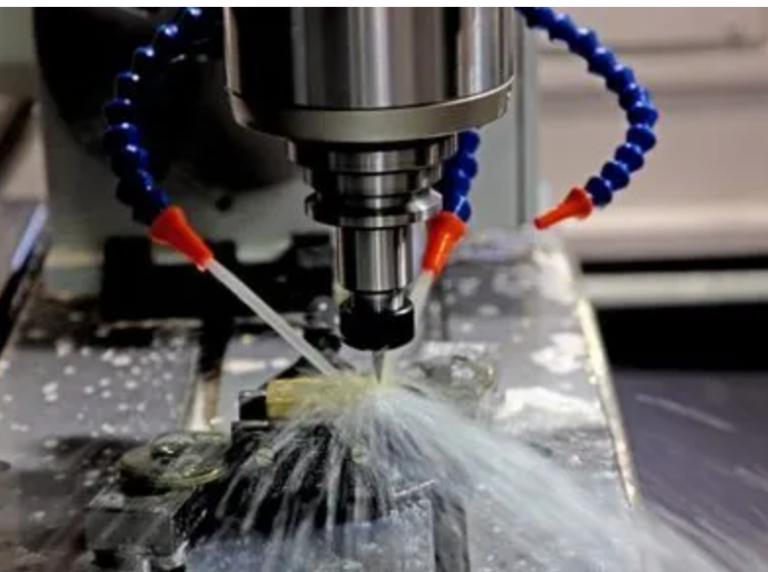

CNC Mineral Casting:

- Process Overview:

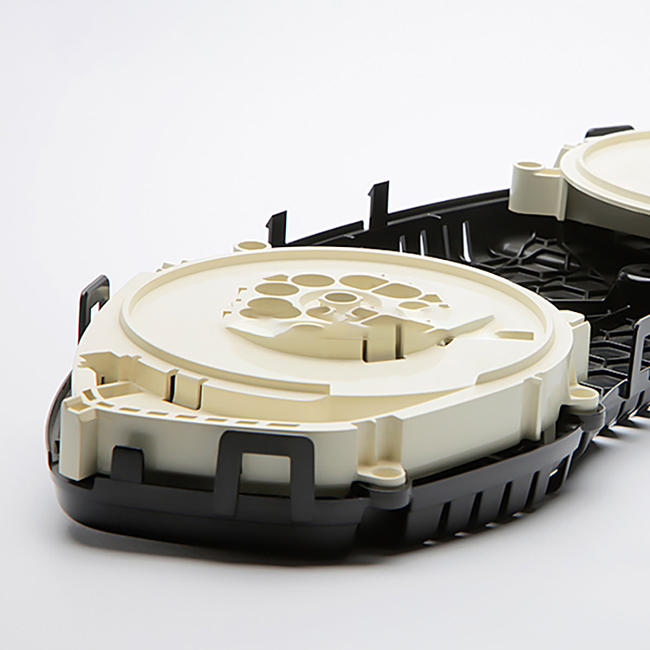

- Material: Typically uses mineral-filled epoxy resin, which is poured into a mold.

- Curing: The resin is cured to form a solid mineral casting with embedded granite or quartz aggregates.

- Machining: After curing, the casting is machined using CNC processes to achieve final dimensions and surface finish.

- Assembly: Components like machine beds, columns, and bases for precision machinery are often produced.

- Advantages:

- Damping Properties: Excellent vibration damping and high rigidity.

- Thermal Stability: Maintains dimensional stability over a wide range of temperatures.

- Design Flexibility: Allows for complex shapes and integrated features.

- Cost-Effective: Reduces machining time and waste compared to traditional cast iron.

- Applications:

- Machine Tools: CNC machine beds, columns, bases.

- Metrology Equipment: Coordinate measuring machines (CMMs).

- Industrial Applications: Semiconductor manufacturing equipment, optical devices.

Comparison:

- Material: Investment casting uses metals/alloys, while CNC mineral casting uses epoxy resin with mineral fillers.

- Complexity: Investment casting excels in intricate details and thin walls. CNC mineral casting offers structural stability and damping.

- Cost: Initial tooling costs are higher for investment casting, but it can be cost-effective for high-volume production. CNC mineral casting can be more economical for low to medium volumes due to reduced machining.

- Application: Investment casting is ideal for precise metal parts with fine details. CNC mineral casting is preferred for machine components requiring stability and vibration damping.