Benefits of Using Plastic Injection Molding for Manufacturing

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is highly versatile and can be used to produce a wide range of products, from small components to large parts. There are many benefits to using plastic injection molding for manufacturing, making it a popular choice for many industries.

One of the key benefits of plastic injection molding is its cost-effectiveness. The initial tooling costs for plastic injection molding can be high, but once the molds are created, the cost per part is relatively low. This makes plastic injection molding a cost-effective option for high-volume production runs. Additionally, the high level of automation in the plastic injection molding process helps to reduce labor costs, further increasing its cost-effectiveness.

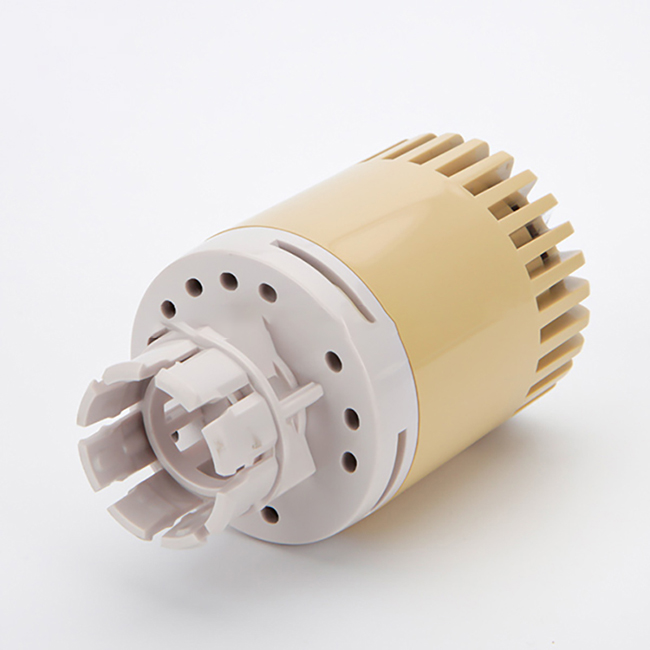

Another benefit of plastic injection molding is its ability to produce complex and intricate parts with high precision. The molds used in plastic injection molding are highly detailed and can be customized to produce parts with tight tolerances. This level of precision is essential for many industries, such as the medical and aerospace industries, where quality and accuracy are paramount.

Plastic injection molding also offers a high level of repeatability and consistency. Once the mold is created and the process is set up, each part produced will be identical to the next. This consistency is crucial for industries that require parts to meet strict specifications and standards. Additionally, the high level of automation in plastic injection molding helps to minimize the risk of human error, further ensuring the consistency of the parts produced.

One of the key advantages of plastic injection molding is its ability to produce parts with a wide range of materials. There are many different types of plastics that can be used in the injection molding process, each with its own unique properties and characteristics. This versatility allows manufacturers to choose the best material for their specific application, whether it be for its strength, flexibility, heat resistance, or other properties.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

Plastic injection molding is also a highly efficient process that can produce parts quickly and with minimal waste. The molds used in plastic injection molding are designed to be used repeatedly, allowing for high-volume production runs. Additionally, the automated nature of the process helps to reduce cycle times, further increasing efficiency. The ability to produce parts quickly and efficiently is essential for industries that require fast turnaround times.

In conclusion, plastic injection molding offers a wide range of benefits for manufacturers. From its cost-effectiveness and precision to its versatility and efficiency, plastic injection molding is a popular choice for many industries. Whether you are producing small components or large parts, plastic injection molding can help you achieve high-quality, consistent results. If you are looking for a reliable and efficient manufacturing process, consider using plastic injection molding for your next project.