Table of Contents

Benefits of Using Plastic Injection Molding for Manufacturing Pet Toys

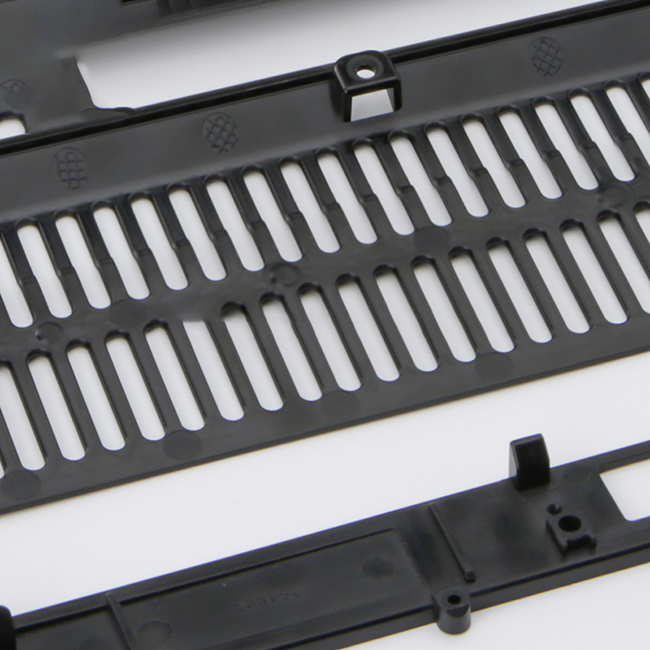

Plastic injection molding is a widely used manufacturing process that has revolutionized the production of various products, including pet toys. This method involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. The process is highly efficient, cost-effective, and versatile, making it an ideal choice for producing a wide range of animal products.

One of the key benefits of using plastic injection molding for manufacturing pet toys is the ability to create complex and intricate designs with high precision. The process allows for the production of detailed and intricate shapes that would be difficult or impossible to achieve with other manufacturing methods. This is particularly important for pet toys, as animals often enjoy toys that are visually stimulating and engaging.

Additionally, plastic injection molding offers a high level of consistency and repeatability in the production process. This means that each pet toy produced will be virtually identical to the next, ensuring a consistent quality and performance for the end consumer. This is crucial for pet toys, as consistency in size, shape, and durability is important for the safety and enjoyment of pets.

Furthermore, plastic injection molding is a cost-effective manufacturing method for producing pet toys in large quantities. The process is highly automated, which reduces labor costs and increases production efficiency. This allows manufacturers to produce pet toys at a lower cost per unit, making them more affordable for consumers. Additionally, the high production speed of plastic injection molding means that manufacturers can quickly ramp up production to meet increased demand, making it an ideal choice for seasonal or promotional pet toys.

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

Another advantage of using plastic injection molding for manufacturing pet toys is the wide range of materials that can be used. This process is compatible with a variety of plastic resins, including durable and flexible materials that are safe for pets to chew on. Manufacturers can choose the most suitable material for their specific pet toy design, ensuring that it meets the required safety and performance standards.

In addition to the benefits mentioned above, plastic injection molding is also an environmentally friendly manufacturing process for producing pet toys. The process generates minimal waste, as any excess plastic material can be recycled and reused in future production runs. This helps to reduce the environmental impact of manufacturing pet toys and promotes sustainability in the industry.

Overall, plastic injection molding offers numerous benefits for manufacturing pet toys, including the ability to create complex designs, consistent quality, cost-effectiveness, material versatility, and environmental sustainability. This manufacturing method is a popular choice for producing a wide range of animal products, from chew toys to interactive playthings. With its efficiency, precision, and versatility, plastic injection molding is a valuable tool for manufacturers looking to create high-quality and engaging pet toys for animal lovers around the world.

How Plastic Injection Molding is Revolutionizing the Production of Animal Feeders and Waterers

Plastic injection molding has long been a popular manufacturing process for a wide range of products, from automotive parts to household items. However, in recent years, this technology has been increasingly utilized in the production of animal feeders and waterers. This shift has revolutionized the way these essential products are manufactured, offering numerous benefits to both manufacturers and consumers alike.

One of the key advantages of plastic injection molding for animal products is its cost-effectiveness. This process allows for the mass production of high-quality feeders and waterers at a relatively low cost, making it an attractive option for manufacturers looking to streamline their production processes. Additionally, the ability to create complex shapes and designs with precision and consistency ensures that each product meets the highest standards of quality and functionality.

Another benefit of plastic injection molding for animal products is its durability. Unlike traditional manufacturing methods, which may result in weak or brittle products, injection molding produces items that are strong, resilient, and long-lasting. This is particularly important for animal feeders and waterers, which are subjected to daily wear and tear in agricultural and industrial settings. By using injection-molded plastic, manufacturers can create products that can withstand the rigors of daily use, ensuring that they remain in good condition for years to come.

In addition to being cost-effective and durable, plastic injection molding also offers a high degree of customization. Manufacturers can easily adjust the size, shape, and color of their products to meet the specific needs of their customers. This flexibility allows for the creation of products that are tailored to the unique requirements of different animal species, ensuring that each feeder and waterer is optimized for maximum efficiency and comfort.

Furthermore, plastic injection molding is a highly efficient process that minimizes waste and reduces environmental impact. Unlike other manufacturing methods that may produce excess material or require multiple steps to create a finished product, injection molding is a streamlined process that generates minimal waste. This not only helps to reduce production costs but also contributes to a more sustainable manufacturing industry.

Overall, plastic injection molding has revolutionized the production of animal feeders and waterers, offering a cost-effective, durable, customizable, and environmentally friendly solution for manufacturers and consumers alike. By harnessing the power of this innovative technology, companies can create high-quality products that meet the needs of a diverse range of animals while also reducing their environmental footprint. As the demand for these essential products continues to grow, plastic injection molding will undoubtedly play a crucial role in shaping the future of the animal care industry.