Table of Contents

Benefits of Using Plastic Injection Molding Machines for Trash Can Manufacturing

Plastic injection molding machines have revolutionized the manufacturing industry, offering a cost-effective and efficient way to produce a wide range of plastic products. One such product that benefits greatly from the use of plastic injection molding machines is the trash can. Trash cans are essential in keeping our homes, offices, and public spaces clean and organized. With the help of plastic injection molding machines, manufacturers can produce high-quality trash cans that are durable, lightweight, and aesthetically pleasing.

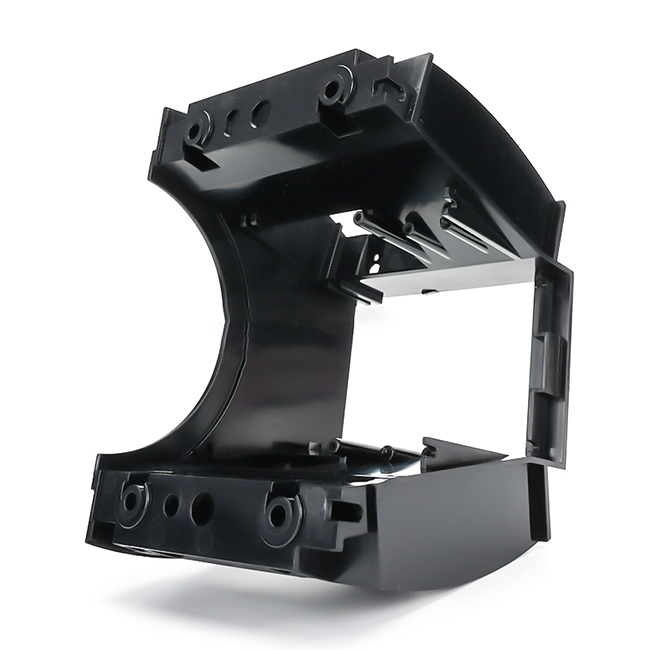

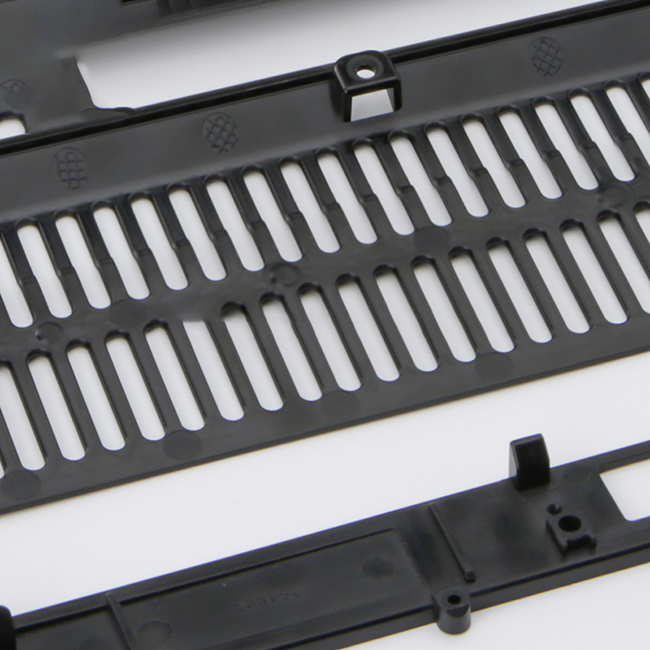

One of the key benefits of using plastic injection molding machines for trash can manufacturing is the ability to create complex and intricate designs with precision and consistency. These machines use molds to shape molten plastic into the desired form, allowing for the production of trash cans with intricate details, such as textured surfaces, embossed logos, and custom shapes. This level of precision is crucial in ensuring that the trash cans meet the required specifications and quality standards.

In addition to precision, plastic injection molding machines offer a high level of efficiency in the manufacturing process. These machines can produce a large number of trash cans in a relatively short amount of time, making them ideal for mass production. This efficiency not only reduces production costs but also allows manufacturers to meet tight deadlines and fulfill large orders in a timely manner.

Furthermore, plastic injection molding machines are versatile and can accommodate a wide range of plastic materials, including polyethylene, polypropylene, and polystyrene. This versatility allows manufacturers to choose the most suitable material for their trash cans based on factors such as durability, flexibility, and cost. By selecting the right material, manufacturers can ensure that the trash cans are able to withstand daily wear and tear, harsh weather conditions, and heavy loads.

Another advantage of using plastic injection molding machines for trash can manufacturing is the ability to produce lightweight yet durable products. Plastic trash cans are much lighter than their metal counterparts, making them easier to transport, handle, and empty. Despite their lightweight nature, plastic trash cans are incredibly durable and resistant to impact, corrosion, and UV radiation. This durability ensures that the trash cans have a long service life and can withstand the rigors of daily use.

Moreover, plastic injection molding machines offer a cost-effective solution for trash can manufacturing. The initial investment in these machines may be high, but the long-term benefits far outweigh the upfront costs. By producing trash cans in large quantities, manufacturers can take advantage of economies of scale and reduce the cost per unit. Additionally, the efficiency of plastic injection molding machines results in minimal material waste, further reducing production costs.

In conclusion, plastic injection molding machines offer numerous benefits for trash can manufacturing, including precision, efficiency, versatility, durability, lightweight design, and cost-effectiveness. These machines have revolutionized the way trash cans are produced, allowing manufacturers to create high-quality products that meet the demands of today’s consumers. Whether for residential, commercial, or industrial use, plastic injection molding machines are an essential tool in the production of trash cans that are functional, durable, and aesthetically pleasing.

How to Choose the Right Plastic Injection Molding Machine for Trash Can Production

Plastic injection molding machines have revolutionized the manufacturing industry, allowing for the mass production of plastic products with precision and efficiency. When it comes to producing trash cans, choosing the right injection molding machine is crucial to ensure high-quality and cost-effective production.

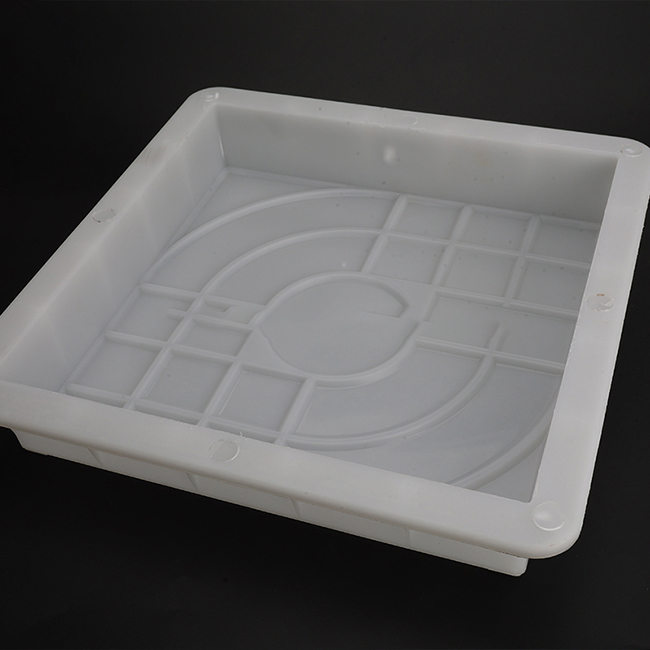

One of the key factors to consider when selecting a plastic injection molding machine for trash can production is the size and capacity of the machine. Trash cans come in various sizes, from small household bins to large industrial containers. It is important to choose a machine that can accommodate the size and volume of trash cans you intend to produce. A machine with a larger clamping force and injection capacity will be able to produce larger trash cans more efficiently.

Another important consideration is the type of plastic material you will be using for the production of trash cans. Different plastics have different melting points and flow properties, so it is essential to choose a machine that is compatible with the type of plastic you will be using. Some machines are designed to work with specific types of plastic, while others are more versatile and can handle a wider range of materials.

In addition to size and material compatibility, it is also important to consider the precision and speed of the injection molding machine. Trash cans require precise molding to ensure a tight seal and durable construction. Look for a machine that offers high precision control and fast cycle times to maximize productivity and minimize waste.

When choosing a plastic injection molding machine for trash can production, it is also important to consider the overall cost of the machine. While it may be tempting to opt for a cheaper machine to save on upfront costs, it is important to consider the long-term costs of maintenance, repairs, and energy consumption. Investing in a high-quality machine from a reputable manufacturer may cost more initially but can save you money in the long run by reducing downtime and increasing efficiency.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

It is also important to consider the level of automation and customization options available with the injection molding machine. Automated machines can increase productivity and reduce labor costs, while customizable machines allow for greater flexibility in production. Consider your specific production needs and choose a machine that offers the right balance of automation and customization for your operation.

In conclusion, choosing the right plastic injection molding machine for trash can production is essential to ensure high-quality, cost-effective manufacturing. Consider factors such as size, material compatibility, precision, speed, cost, automation, and customization when selecting a machine for your operation. By carefully evaluating your production needs and choosing a machine that meets those requirements, you can optimize your production process and achieve success in the manufacturing of trash cans.