Table of Contents

Benefits of Using Plastic Mold Injection Molding for Fishing Lures

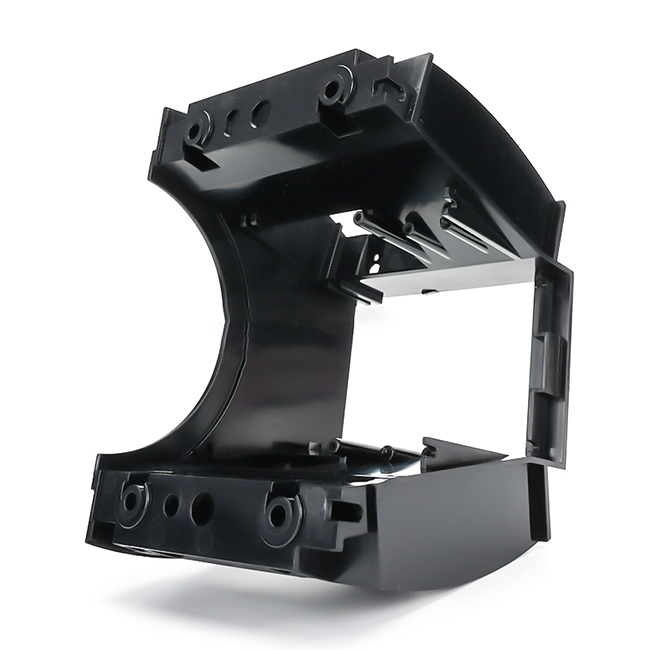

Plastic mold injection molding is a popular manufacturing process used in various industries, including the production of fishing lures. This method involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. There are several benefits to using plastic mold injection molding for fishing lures, making it a preferred choice for many manufacturers in the fishing tackle industry.

One of the key advantages of plastic mold injection molding is its ability to produce high-quality, consistent parts with tight tolerances. This is crucial in the production of fishing lures, where precision and accuracy are essential for achieving the desired performance and appearance. The mold cavity can be designed to create intricate details and complex shapes, allowing for the production of realistic and attractive fishing lures that are sure to attract fish.

Another benefit of plastic mold injection molding for fishing lures is its cost-effectiveness. Once the mold is created, it can be used repeatedly to produce large quantities of identical parts at a relatively low cost per unit. This makes it an efficient and economical manufacturing process, especially for mass production of fishing lures. Additionally, the high production speed of plastic mold injection molding allows for quick turnaround times, ensuring that manufacturers can meet the demands of the market in a timely manner.

Plastic mold injection molding also offers versatility in terms of material selection. There are various types of plastic resins available that can be used in the injection molding process, each with its own unique properties and characteristics. Manufacturers can choose the most suitable material for their fishing lures based on factors such as durability, flexibility, and buoyancy. This flexibility allows for the production of fishing lures that are tailored to specific fishing conditions and target species, enhancing their performance and effectiveness on the water.

Furthermore, plastic mold injection molding enables the production of fishing lures in a wide range of sizes, shapes, and colors. Manufacturers can easily customize their designs to create a diverse selection of fishing lures that cater to different fishing preferences and techniques. Whether anglers prefer topwater lures, crankbaits, jigs, or soft plastics, plastic mold injection molding can accommodate a variety of styles and designs to suit every angler’s needs.

In conclusion, plastic mold injection molding offers numerous benefits for the production of fishing lures. From high-quality and consistent parts to cost-effectiveness and versatility in material selection, this manufacturing process provides manufacturers with the tools they need to create innovative and effective fishing lures that are sure to enhance the fishing experience for anglers of all skill levels. By harnessing the power of plastic mold injection molding, manufacturers can continue to push the boundaries of fishing lure design and performance, ensuring that anglers have access to the best tools for their fishing adventures.

How to Choose the Right Plastic Material for Injection Molding Fishing Tackle

Plastic mold injection molding is a popular method for producing fishing tackle due to its cost-effectiveness and versatility. However, choosing the right plastic material for injection molding fishing tackle is crucial to ensure the durability and performance of the final product. There are several factors to consider when selecting a plastic material for injection molding fishing tackle, including the type of fishing tackle being produced, the desired properties of the final product, and the manufacturing process.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

One of the most important factors to consider when choosing a plastic material for injection molding fishing tackle is the type of fishing tackle being produced. Different types of fishing tackle, such as lures, hooks, and bobbers, require different properties in order to perform effectively. For example, lures need to be lightweight and buoyant, while hooks need to be strong and durable. By understanding the specific requirements of the fishing tackle being produced, manufacturers can choose a plastic material that will meet these requirements and ensure the quality of the final product.

In addition to the type of fishing tackle being produced, manufacturers must also consider the desired properties of the final product when selecting a plastic material for injection molding. Properties such as strength, flexibility, and resistance to corrosion are important factors to consider when choosing a plastic material for fishing tackle. For example, if a manufacturer is producing fishing hooks, they may choose a plastic material that is strong and resistant to corrosion in order to ensure the durability of the final product. By considering the desired properties of the final product, manufacturers can choose a plastic material that will meet these requirements and ensure the quality of the final product.

Another important factor to consider when choosing a plastic material for injection molding fishing tackle is the manufacturing process. Different plastic materials have different properties that can affect the injection molding process, such as melt flow rate, shrinkage, and cooling time. By understanding how these properties will impact the manufacturing process, manufacturers can choose a plastic material that will be easy to work with and produce high-quality fishing tackle. Additionally, manufacturers must consider the cost of the plastic material when selecting a material for injection molding fishing tackle. Some plastic materials may be more expensive than others, so manufacturers must balance the desired properties of the final product with the cost of the material in order to produce fishing tackle that is both high-quality and cost-effective.

In conclusion, choosing the right plastic material for injection molding fishing tackle is crucial to ensure the durability and performance of the final product. By considering factors such as the type of fishing tackle being produced, the desired properties of the final product, and the manufacturing process, manufacturers can choose a plastic material that will meet these requirements and produce high-quality fishing tackle. By carefully selecting a plastic material for injection molding fishing tackle, manufacturers can ensure the success of their products and meet the needs of their customers.