Benefits of Using Injection Molding for Plastic Pallets

Plastic pallets are a popular choice for transporting goods in various industries due to their durability, versatility, and cost-effectiveness. When it comes to manufacturing plastic pallets, injection molding is a widely used process that offers numerous benefits. In this article, we will explore the advantages of using injection molding for producing plastic pallets.

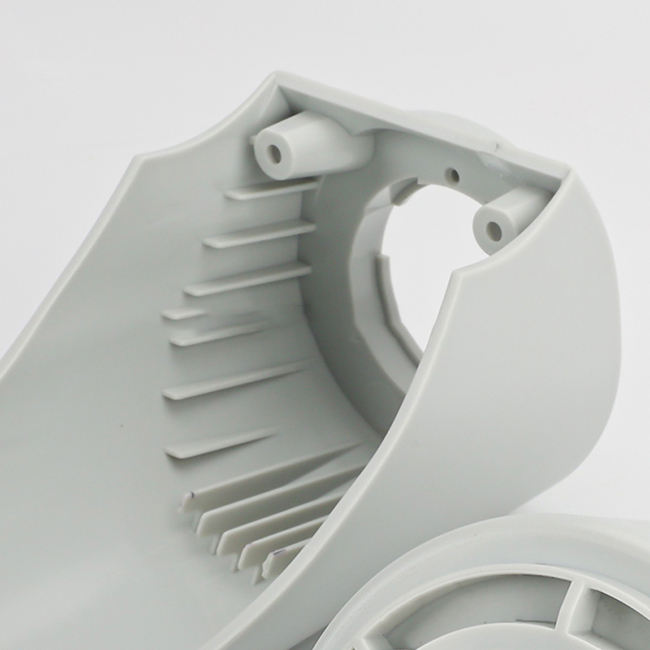

Injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. This process is highly efficient and allows for the production of large quantities of plastic pallets in a relatively short amount of time. The ability to mass-produce plastic pallets using injection molding makes it a cost-effective option for businesses looking to streamline their production processes.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

One of the key benefits of using injection molding for plastic pallets is the high level of precision and consistency it offers. The molds used in injection molding are designed to exact specifications, ensuring that each plastic pallet produced is identical in size, shape, and quality. This level of precision is crucial for industries that require uniformity in their pallets to ensure smooth and efficient operations.

Another advantage of injection molding for plastic pallets is the wide range of customization options it provides. Manufacturers can easily adjust the design, size, and color of plastic pallets to meet the specific needs of their customers. This flexibility allows businesses to create pallets that are tailored to their unique requirements, whether it be for a specific industry, application, or branding purposes.

Injection molding also offers excellent strength and durability, making plastic pallets produced through this process highly resistant to wear and tear. The molten plastic material is injected into the mold cavity under high pressure, resulting in a dense and solid structure that can withstand heavy loads and rough handling. This durability is essential for industries that rely on plastic pallets to transport goods safely and securely.

Furthermore, injection molding is a sustainable manufacturing process that minimizes waste and reduces environmental impact. The molds used in injection molding are typically made from durable materials such as steel or aluminum, allowing them to be reused multiple times without losing their shape or quality. This reduces the amount of waste generated during the production of plastic pallets and helps businesses lower their carbon footprint.

In conclusion, injection molding is a highly efficient and cost-effective process for producing plastic pallets that offers numerous benefits. From precision and consistency to customization options and durability, injection molding provides businesses with a reliable solution for their pallet manufacturing needs. By choosing injection molding for plastic pallet production, companies can enjoy a high-quality product that meets their specific requirements while also contributing to a more sustainable manufacturing process.