Benefits of Plastic Tube Injection Molding

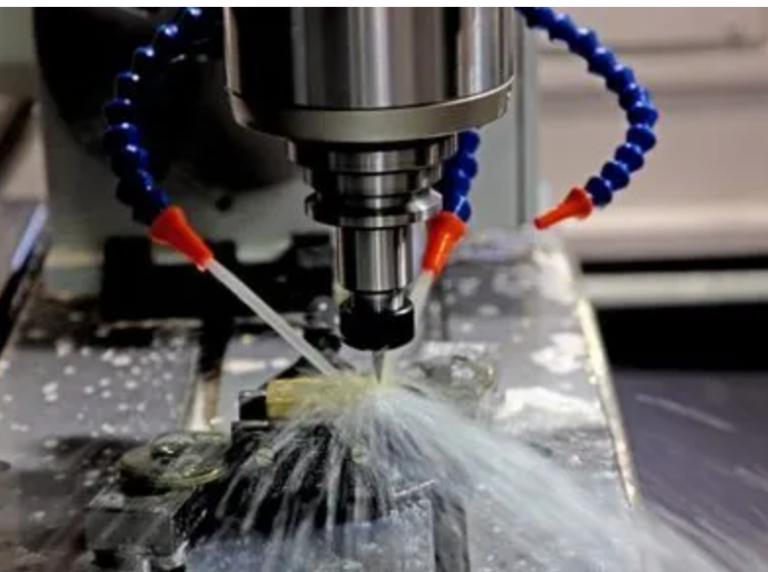

Plastic tube injection molding is a widely used manufacturing process that offers a multitude of benefits for various industries. This process involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form a tube shape. The versatility and efficiency of plastic tube injection molding make it a popular choice for producing a wide range of products, from medical devices to household items.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

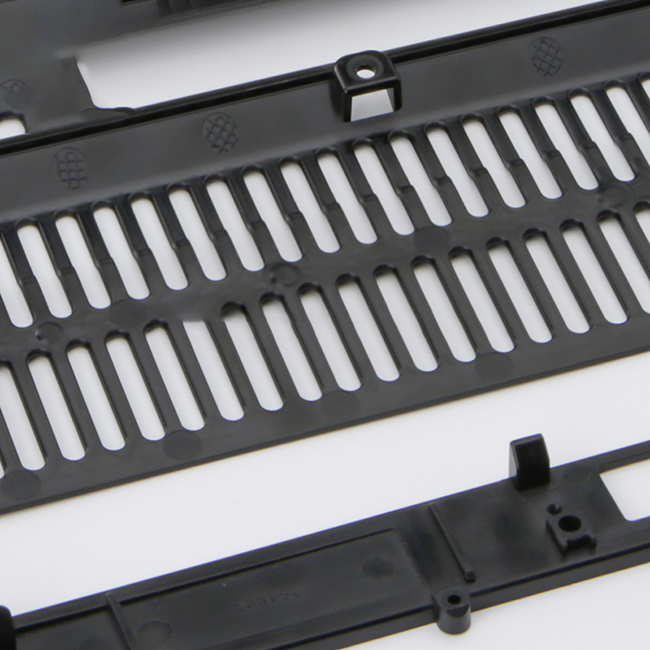

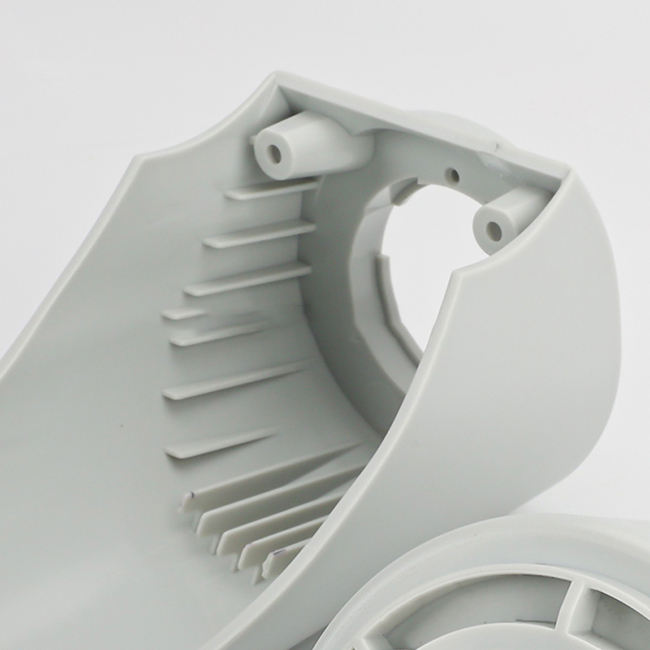

One of the key benefits of plastic tube injection molding is its ability to create complex shapes with high precision. The mold cavity can be designed to produce tubes with intricate details and features, such as threads, ribs, and undercuts. This level of precision is essential for many applications where tight tolerances are required for proper functionality.

Another advantage of plastic tube injection molding is its cost-effectiveness. The process allows for high-volume production at a relatively low cost per unit, making it an economical choice for mass production. Additionally, the use of automated machinery and streamlined production processes help reduce labor costs and increase efficiency.

Plastic tube injection molding also offers a high level of repeatability and consistency. Once the mold is set up and the parameters are dialed in, the process can be repeated with minimal variation in the final product. This consistency is crucial for ensuring product quality and meeting strict specifications.

Furthermore, plastic tube injection molding is a versatile process that can accommodate a wide range of materials. Different types of plastics can be used in the injection molding process, each with its own unique properties and characteristics. This flexibility allows manufacturers to choose the most suitable material for their specific application, whether it be for its strength, flexibility, or chemical resistance.

In addition to its technical advantages, plastic tube injection molding is also environmentally friendly. The process generates minimal waste, as any excess material can be recycled and reused in future production runs. This sustainability aspect is becoming increasingly important in today’s eco-conscious society, where reducing waste and minimizing environmental impact are top priorities.

Overall, plastic tube injection molding offers a host of benefits for manufacturers looking to produce high-quality, cost-effective products. Its ability to create complex shapes with precision, its cost-effectiveness, repeatability, versatility in material selection, and environmental sustainability make it a highly attractive option for a wide range of industries.

In conclusion, plastic tube injection molding is a versatile and efficient manufacturing process that provides numerous benefits for manufacturers. Its ability to produce complex shapes with high precision, its cost-effectiveness, repeatability, versatility in material selection, and environmental sustainability make it a valuable tool for producing a wide range of products. Whether it be for medical devices, household items, or industrial components, plastic tube injection molding offers a reliable and efficient solution for meeting the demands of today’s competitive market.