Benefits of Using Polystyrene Plastic Pellets for Injection Molding

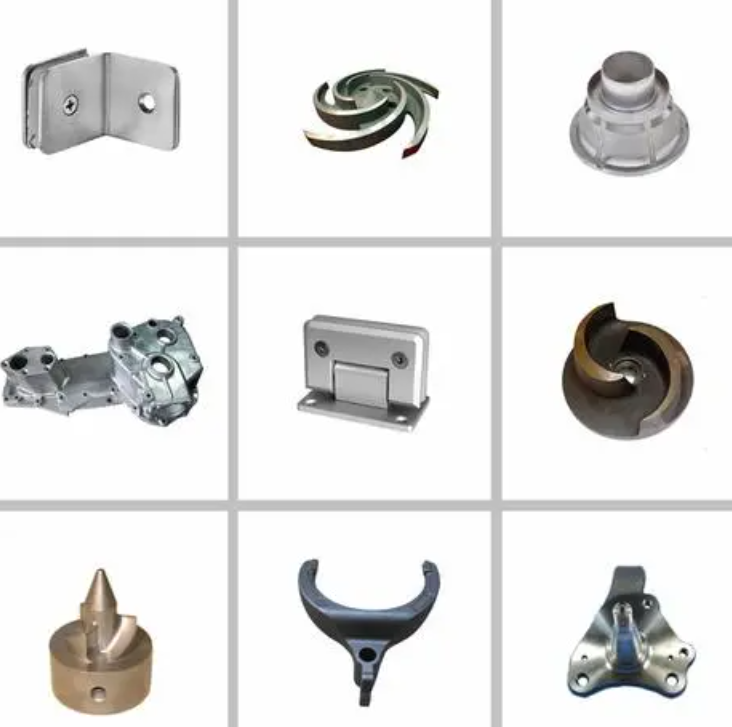

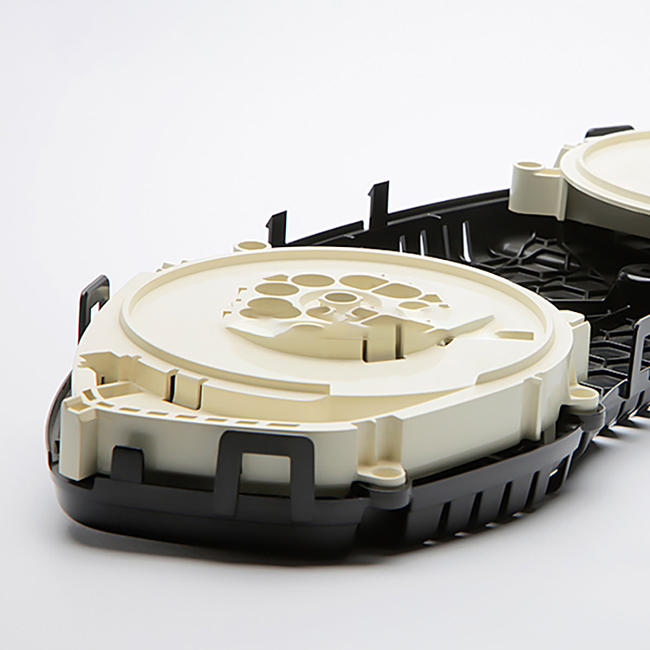

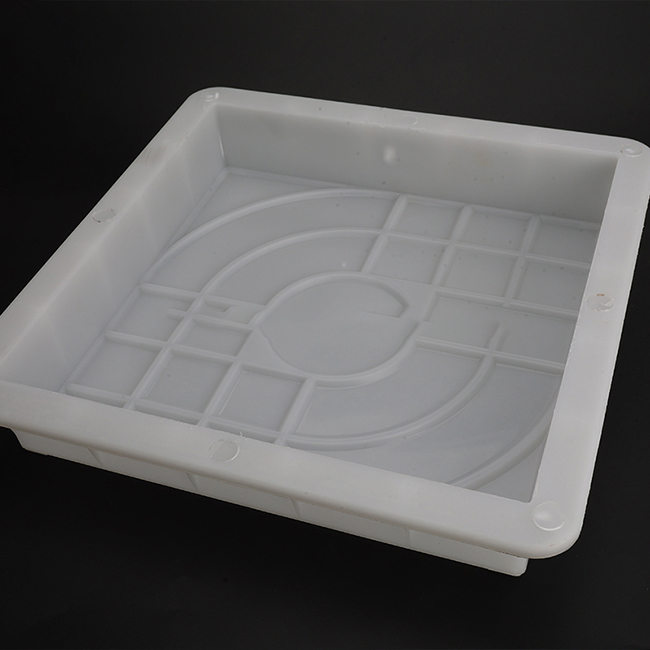

Polystyrene plastic pellets are a popular choice for injection molding due to their numerous benefits. Injection molding is a manufacturing process that involves injecting molten material into a mold cavity, where it cools and hardens to form a desired shape. Polystyrene plastic pellets are a versatile material that can be used in a wide range of applications, making them a popular choice for manufacturers looking to produce high-quality products efficiently and cost-effectively.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

One of the key benefits of using polystyrene plastic pellets for injection molding is their versatility. Polystyrene is a thermoplastic polymer that can be easily molded into a variety of shapes and sizes, making it ideal for a wide range of applications. Whether you are producing small, intricate parts or large, complex components, polystyrene plastic pellets can be tailored to meet your specific needs.

In addition to their versatility, polystyrene plastic pellets are also known for their durability. Polystyrene is a strong and resilient material that can withstand high temperatures and pressures, making it ideal for use in injection molding processes. This durability ensures that products made from polystyrene plastic pellets are long-lasting and able to withstand the rigors of everyday use.

Another benefit of using polystyrene plastic pellets for injection molding is their cost-effectiveness. Polystyrene is a relatively inexpensive material compared to other plastics, making it an attractive option for manufacturers looking to reduce production costs. Additionally, polystyrene plastic pellets can be recycled and reused, further reducing waste and lowering overall production costs.

Polystyrene plastic pellets are also known for their excellent dimensional stability. When molded into a specific shape, polystyrene plastic pellets retain their shape and size over time, ensuring that products maintain their integrity and functionality. This dimensional stability is crucial for manufacturers looking to produce high-quality products that meet strict specifications and standards.

Furthermore, polystyrene plastic pellets are lightweight and easy to handle, making them ideal for use in injection molding processes. Their low density allows for easy transportation and storage, while their ease of handling ensures that production processes run smoothly and efficiently. This makes polystyrene plastic pellets a practical choice for manufacturers looking to streamline their operations and increase productivity.

In conclusion, polystyrene plastic pellets offer a wide range of benefits for manufacturers looking to produce high-quality products efficiently and cost-effectively. Their versatility, durability, cost-effectiveness, dimensional stability, and ease of handling make them an ideal choice for injection molding processes. Whether you are producing small, intricate parts or large, complex components, polystyrene plastic pellets can be tailored to meet your specific needs. Consider using polystyrene plastic pellets for your next injection molding project and experience the numerous benefits they have to offer.