- Materials Expertise: Ensure the service provider has experience working with both plastic and steel materials. They should understand the properties of each material and how to machine them effectively.

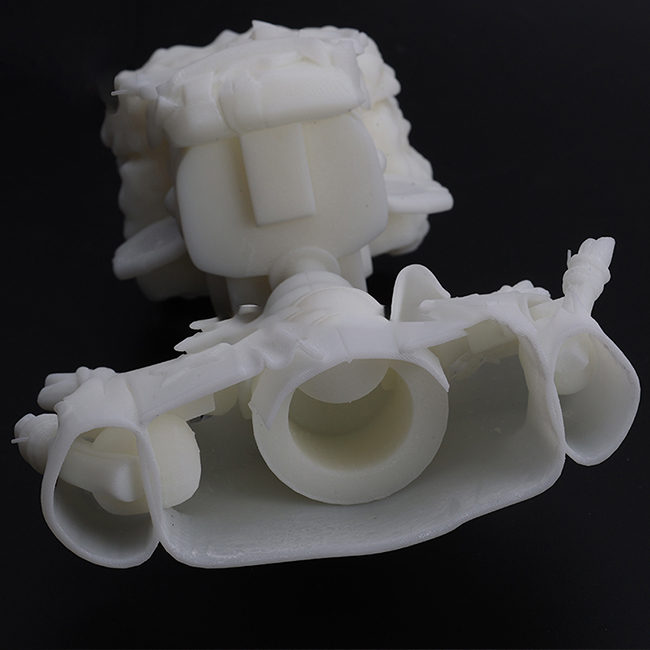

- Prototyping Techniques: Different techniques can be used for prototyping, including CNC machining, 3D printing, injection molding, and more. Depending on your project requirements, choose a service that offers the appropriate technique.

- Quality and Accuracy: Prototypes should accurately represent your design. Look for providers with a track record of delivering high-quality prototypes that match your specifications.

- Customization and Flexibility: Your prototyping needs may vary based on design changes or iterations. Choose a service that can accommodate customization and provide flexibility in terms of quantities and timelines.

- Additional Services: Some providers offer additional services such as CAD design support, finishing options (like painting or polishing), and even assembly. These can be beneficial if you need comprehensive prototyping support.

- Cost and Time Efficiency: Compare quotes from different services to ensure competitive pricing. Also, consider turnaround times and how efficiently they can deliver prototypes.