Benefits of Using Recycled Plastic in Injection Molding

Recycled plastic injection molding is a process that involves melting down plastic materials and injecting them into a mold to create a wide range of products. This method of manufacturing has gained popularity in recent years due to its numerous benefits, both for the environment and for businesses. In this article, we will explore the advantages of using recycled plastic in injection molding.

One of the primary benefits of using recycled plastic in injection molding is its positive impact on the environment. By using recycled materials, manufacturers can reduce the amount of plastic waste that ends up in landfills or oceans. This helps to conserve natural resources and reduce the carbon footprint of the manufacturing process. Additionally, recycling plastic helps to decrease the demand for new plastic production, which in turn reduces the consumption of fossil fuels and the emission of greenhouse gases.

Another advantage of using recycled plastic in injection molding is its cost-effectiveness. Recycled plastic materials are often less expensive than virgin plastic, making them a more affordable option for manufacturers. This can help businesses save money on production costs and increase their profit margins. Additionally, using recycled plastic can also help companies meet their sustainability goals and attract environmentally-conscious consumers.

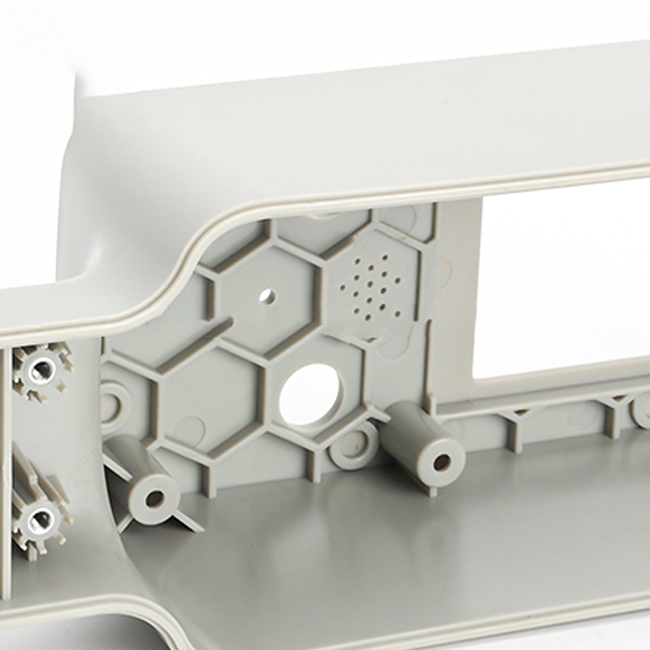

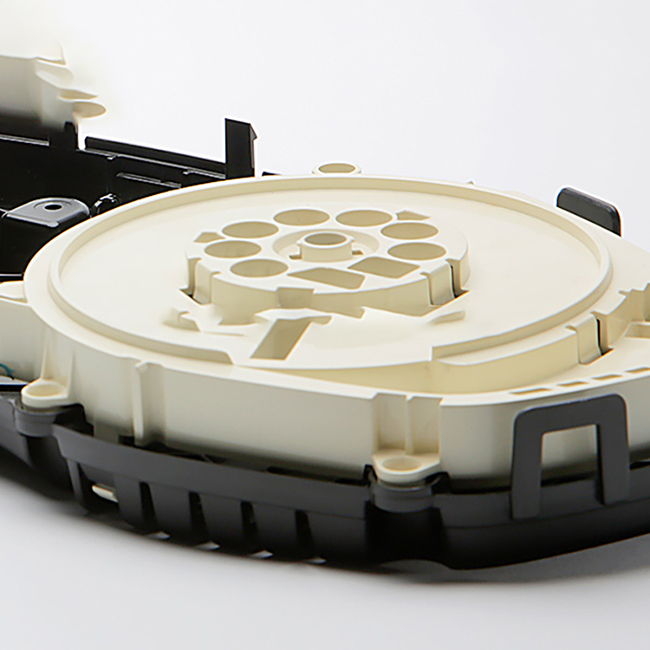

In addition to its environmental and economic benefits, using recycled plastic in injection molding can also improve the quality of the final products. Recycled plastic materials are often just as durable and reliable as virgin plastic, making them suitable for a wide range of applications. By using recycled plastic, manufacturers can create high-quality products that meet the same standards as those made from virgin plastic. This can help businesses maintain their reputation for producing top-notch products while also reducing their environmental impact.

Furthermore, using recycled plastic in injection molding can help businesses comply with regulations and standards related to sustainability and waste management. Many governments and organizations are implementing policies to encourage the use of recycled materials in manufacturing processes. By incorporating recycled plastic into their production methods, businesses can demonstrate their commitment to sustainability and align themselves with these regulations. This can help companies avoid fines and penalties for non-compliance and improve their reputation among consumers and stakeholders.

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

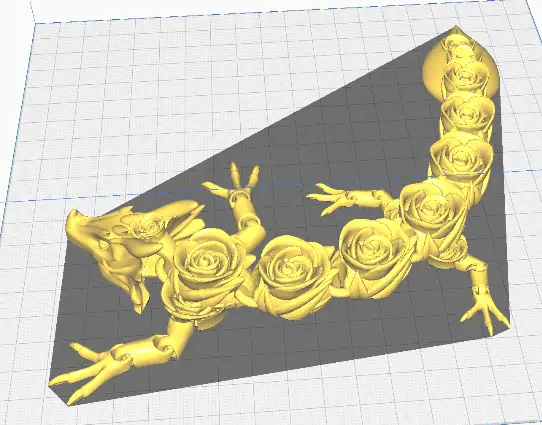

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

Overall, the benefits of using recycled plastic in injection molding are numerous and far-reaching. From reducing plastic waste and conserving natural resources to saving money on production costs and improving product quality, there are many reasons why businesses should consider incorporating recycled plastic into their manufacturing processes. By making the switch to recycled plastic, companies can not only help protect the environment but also enhance their bottom line and strengthen their brand image. In conclusion, recycled plastic injection molding is a sustainable and cost-effective solution that offers a wide range of benefits for businesses and the planet.