Have you heard of SA ingredients?

SA (SAN–styrene-acrylonitrile copolymer/super glue)

SA (SAN–styrene-acrylonitrile copolymer/super glue)

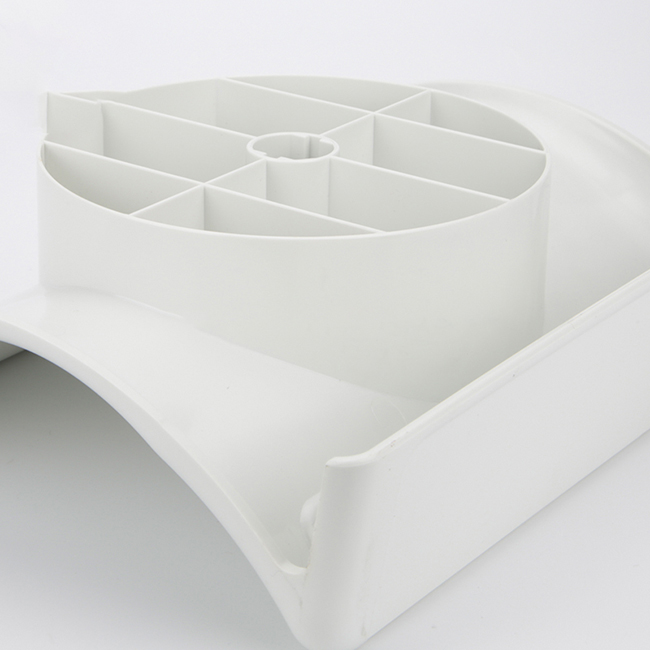

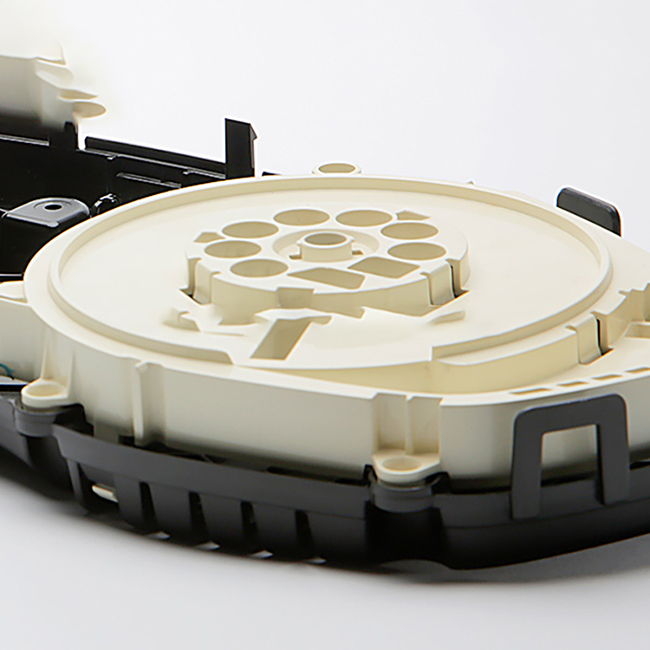

Designing injection molded plastic parts involves several key considerations to ensure successful manufacturing and optimal performance of the final product. Here are some important aspects to keep in mind: 1.Part Geometry: The geometry of the part should be carefully designed to facilitate the injection molding process. This includes minimizing the use of undercuts, sharp corners,…

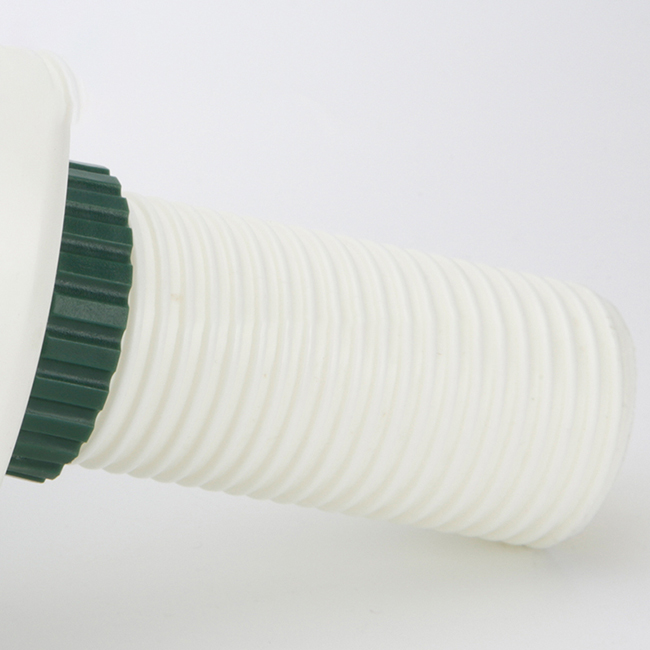

Advantages of Using Injection Molding Machines for Plastic Cup Production Injection molding machines have revolutionized the way plastic cups are produced in the manufacturing industry. These machines offer a wide range of advantages that make them the preferred choice for many companies looking to mass-produce plastic cups efficiently and cost-effectively. One of the key advantages…

Advantages of Using HDPE Injection Molding for Plastic Products High-Density Polyethylene (HDPE) injection molding is a popular method for producing a wide range of plastic products. This process involves melting plastic pellets and injecting them into a mold to create a specific shape. HDPE is a versatile material that offers many advantages for manufacturers looking…

Benefits of Using Plastic Injection Molding Machine Boxes for Packaging Plastic injection molding machine boxes have become increasingly popular in the packaging industry due to their numerous benefits. These boxes are made using a process called plastic injection molding, which involves melting plastic pellets and injecting them into a mold to create a specific shape….

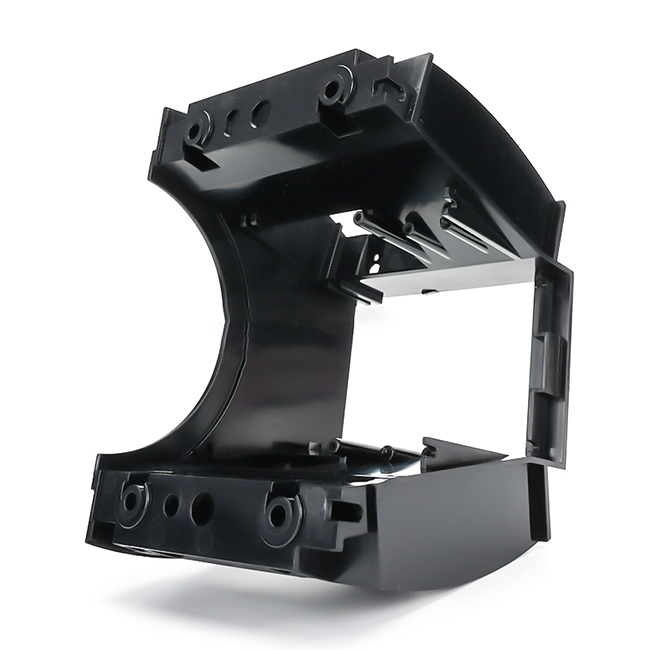

Benefits of Using ABS Plastic in Automotive Injection Molding Automotive injection molding is a widely used manufacturing process in the automotive industry. It involves injecting molten material into a mold cavity, where it cools and solidifies to form the desired part. One of the most commonly used materials in automotive injection molding is ABS plastic….

Benefits of Using a 450 Ton Plastic Injection Molding Machine Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process allows for the production of a wide range of plastic parts and products with high precision and efficiency. One key factor in the success…

Plastik qarshi kalıplamada alyuminiy qoliplardan foydalanishning afzalliklari Plastik inyeksion kalıplama keng qo’llaniladigan ishlab chiqarish jarayoni bo’lib, eritilgan plastik materialni qolip bo’shlig’iga quyishni o’z ichiga oladi. Keyin plastik material soviydi va qolib, mog’or bo’shlig’ining shaklini oladi. Bu jarayon kichik qismlardan tortib katta qismlargacha bo’lgan keng turdagi plastmassa mahsulotlarini ishlab chiqarish uchun ishlatiladi. Plastik qarshi kalıplama jarayonining…

Plastik tushlik qutisini quyish texnologiyasidan foydalanishning afzalliklari Plastik tushlik qutisini quyish texnologiyasi tushlik qutilarini ishlab chiqarish usulini inqilob qildi. Ushbu innovatsion jarayon aniq o’lchamlari va murakkab dizayndagi tushlik qutisini yaratish uchun qolipga eritilgan plastmassani quyishni o’z ichiga oladi. Plastik tushlik qutisini quyish texnologiyasidan foydalanishning bir qancha afzalliklari bor, bu uni butun dunyo bo’ylab ishlab chiqaruvchilar…

Inyeksion kalıplama qismlari uchun ABS materialidan foydalanishning afzalliklari ABS (Akrilonitril Butadien Stirol) – inyeksion kalıplama jarayonlarida keng qo’llaniladigan mashhur termoplastik polimer. U mukammal mexanik xususiyatlarga ega yuqori sifatli qismlarni ishlab chiqarish uchun ideal material bo’lgan bir qator afzalliklarni taqdim etadi. Ushbu maqolada biz inyeksion kalıplama qismlari uchun ABS materialidan foydalanishning afzalliklarini o’rganamiz. ABS materialining asosiy…

Plastik ishlab chiqarishda ikki rangli quyishning afzalliklari Ikki rangli inyeksion kalıplama – bu bitta qismni yaratish uchun qolipga ikki xil rangdagi plastmassani quyishni o’z ichiga olgan jarayon. Ushbu uslub odatda ishlab chiqarish sanoatida noyob rang kombinatsiyasi va dizayndagi mahsulotlarni ishlab chiqarish uchun ishlatiladi. Plastmassa ishlab chiqarishda ikki rangli quyma qolipdan foydalanishning bir qancha afzalliklari bor….

Ishlab chiqarish jarayonlarida Gaiti plastik qarshi puflashdan foydalanishning afzalliklari Plastik qarshi puflash – bu keng qo’llaniladigan ishlab chiqarish jarayoni bo’lib, kerakli shaklni yaratish uchun eritilgan plastmassani qolipga quyishni o’z ichiga oladi. Gaiti plastik qarshi puflash – bu ishlab chiqaruvchilar uchun bir nechta afzalliklarni taqdim etadigan o’ziga xos turdagi qarshi zarbasi. Ushbu maqolada biz ishlab chiqarish…