Table of Contents

Linzalarni ishlab chiqarish uchun plastik inyeksion kalıplamaning afzalliklari

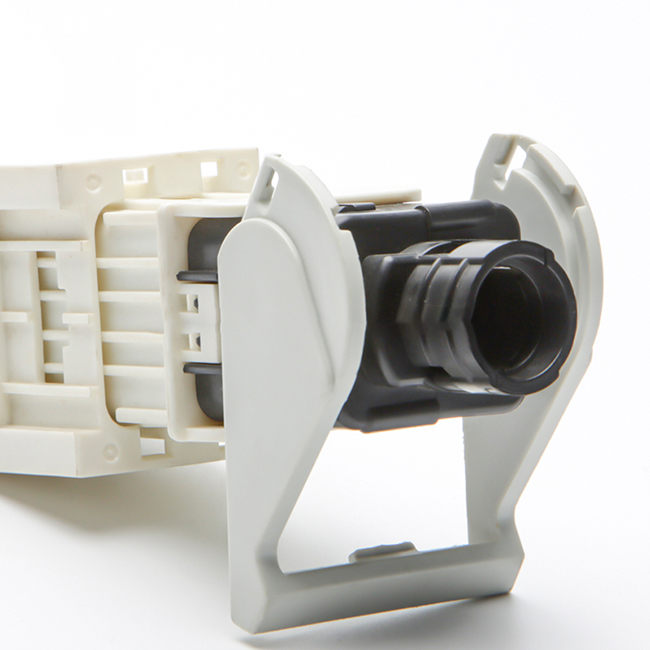

Plastik inyeksion kalıplama keng qo’llaniladigan ishlab chiqarish jarayoni bo’lib, eritilgan plastik materialni qolip bo’shlig’iga quyishni o’z ichiga oladi. Ushbu jarayon odatda keng turdagi mahsulotlarni, shu jumladan linzalarni ishlab chiqarishda qo’llaniladi. Plastik kalıplama linzalari boshqa ishlab chiqarish usullariga nisbatan bir qator afzalliklarni taqdim etadi, bu ularni ko’plab kompaniyalar uchun mashhur tanlovga aylantiradi.

Linzalarni ishlab chiqarish uchun plastik inyeksion kalıplamaning asosiy afzalliklaridan biri murakkab shakllarni yuqori aniqlik bilan ishlab chiqarish qobiliyatidir. Qolib bo’shlig’i boshqa ishlab chiqarish usullari bilan erishish qiyin yoki imkonsiz bo’lgan murakkab linzalar dizaynini yaratish uchun mo’ljallangan bo’lishi mumkin. Bu aniqlik linzalar uchun juda muhim, bunda hatto kichik kamchiliklar ham yakuniy mahsulotning ishlashiga ta’sir qilishi mumkin.

| Yuza ishlov berish | Cilalash pardasi / Slik Print / Teksturali pardozlash / Kauchuk bo’yoq / Yaltiroq pardozlash / Bo’yash / Slik-Screen / Pad Print / EMI qoplamasi / Elektron qoplama / Lazerli markalash / hk. |

| Ishlab chiqarish jarayoni | Buyurtmalar-xom ashyo-ishlab chiqarish-sifat nazorati-qadoqlash-jo’natish |

| Texnologiya | Ko’piklash / Oddiy quyish / Strukturaviy ko’pikli kalıplama / Ortiqcha qoliplash / Gaz yordamida quyish |

Linzalar uchun plastik inyeksion kalıplamaning yana bir afzalligi bu katta hajmdagi linzalarni tez va tejamkor ishlab chiqarish qobiliyatidir. Qolib yaratilgandan so’ng, inyeksion kalıplama jarayoni avtomatlashtirilishi mumkin, bu esa minimal mehnat xarajatlari bilan yuqori hajmli ishlab chiqarish imkonini beradi. Bu plastik qoliplash linzalarini katta miqdorda linzalar ishlab chiqarmoqchi bo‘lgan kompaniyalar uchun tejamkor variantga aylantiradi.

Plastik inyeksion kalıplama shuningdek, keng turdagi plastik materiallardan foydalanish imkoniyatini beradi. Har xil turdagi plastmassalar shaffoflik, chidamlilik va kimyoviy moddalarga qarshilik kabi turli xil xususiyatlarga ega. Linzalar uchun to’g’ri plastik materialni tanlab, ishlab chiqaruvchilar yakuniy mahsulot ularni qo’llashning o’ziga xos talablariga javob berishini ta’minlashi mumkin.

Aniqlik, iqtisodiy samaradorlik va materialning moslashuvchanligi afzalliklaridan tashqari, linzalar uchun plastik inyeksion kalıplama ham taklif qiladi. mustahkamlikning afzalligi. Inyeksion kalıplama jarayoni har bir tsikl bilan bir xil linzalarni ishlab chiqaradi, bu esa barcha linzalarning bir xil yuqori sifat standartlariga javob berishini ta’minlaydi. Bu izchillik tibbiy asboblar yoki optik asboblar kabi bir xillik muhim bo’lgan ilovalar uchun juda muhimdir.

Linzalarni plastik qoliplashda aniqlik va sifatga qanday erishish mumkin

Plastik inyeksion kalıplama ko’p miqdorda plastik qismlarni ishlab chiqarish uchun keng qo’llaniladigan ishlab chiqarish jarayonidir. Bu yuqori aniqlik va aniqlik bilan murakkab shakllarni ishlab chiqarish imkonini beruvchi iqtisodiy va samarali usuldir. Linzalarni plastik qoliplash haqida gap ketganda, optimal ishlash va funksionallikni ta’minlash uchun aniqlik va sifatga erishish juda muhimdir.

Linzalarni plastik qoliplashda aniqlikka erishishning asosiy omillaridan biri qolipning dizayni hisoblanadi. Ob’ektivning shakli va o’lchamlarini aniq takrorlash uchun qolip ehtiyotkorlik bilan ishlab chiqilishi kerak. Bu qattiq toleranslarga ega linzalarni ishlab chiqarishi mumkin bo’lgan qolipni yaratish uchun ilg’or SAPR dasturiy ta’minotidan va aniq ishlov berish usullaridan foydalanishni talab qiladi.

Qlip dizaynidan tashqari, to’g’ri materiallarni tanlash ham linzalarni plastik qoliplashda sifatga erishishda muhim ahamiyatga ega. Materialni tanlash optik tiniqlik, zarba qarshiligi va chidamlilik kabi linzalarning o’ziga xos talablariga bog’liq bo’ladi. Polikarbonat va akril mukammal optik xususiyatlari va yuqori zarba qarshiligi tufayli linzalarni shakllantirish uchun keng qo’llaniladigan materiallardir.

Qlip dizayni va material tanlash tugallangandan so’ng, plastik qarshi kalıplama jarayoni boshlanishi mumkin. Bu jarayon yuqori bosim ostida qolib bo’shlig’iga eritilgan plastik materialni quyishni o’z ichiga oladi. Keyin material sovutiladi va linza shaklini hosil qilish uchun qattiqlashadi. Izchil sifat va aniqlikni ta’minlash uchun qoliplash jarayonida harorat, bosim va sovutish tezligini yaqindan kuzatib borish va nazorat qilish muhimdir.

Linzalarni plastik qoliplashda aniqlik va sifatni yanada oshirish uchun, abraziv va qoplama kabi keyingi ishlov berish usullari. ishga joylashishi mumkin. Ob’ektiv yuzasini jilolash optik tiniqlikni yaxshilash va sirt kamchiliklarini kamaytirishi mumkin, qoplama esa chidamlilik va tirnalgan va ishqalanishga chidamliligini oshirishi mumkin.

Sifatni nazorat qilish linzalarni plastik qoliplashda aniqlikka erishishning yana bir muhim jihati hisoblanadi. Linzalarni havo pufakchalari, egrilik yoki sirt nosimmetrikliklari kabi nuqsonlarni tekshirish faqat yuqori sifatli linzalar ishlab chiqarilishini ta’minlash uchun zarurdir. Avtomatlashtirilgan tekshirish tizimlari nuqsonli linzalarni aniqlash va rad etish uchun ishlatilishi mumkin, bu esa mijozlarga faqat benuqson mahsulotlar yetkazib berilishini ta’minlaydi.

Xulosa qilib aytadigan bo’lsak, linzalarni plastik qoliplashda aniqlik va sifatga erishish qolip dizayni, material tanlash, jarayonda detallarga diqqat bilan e’tibor berishni talab qiladi. nazorat qilish, qayta ishlashdan keyingi va sifat nazorati. Eng yaxshi amaliyotlarga rioya qilish va ilg’or texnologiyalardan foydalangan holda ishlab chiqaruvchilar eng yuqori ishlash va ishonchlilik standartlariga javob beradigan linzalarni ishlab chiqarishlari mumkin. Plastik qarshi kalıplama turli sohalarda, jumladan, avtomobilsozlik, tibbiyot va maishiy elektronika uchun zarur bo’lgan yuqori sifatli linzalarni ishlab chiqarishning ko’p qirrali va samarali usuli bo’lib qolmoqda. To’g’ri tajriba va resurslar bilan ishlab chiqaruvchilar linzalarni plastik kalıplamada ajoyib natijalarga erishishlari va bugungi raqobatbardosh bozor talablariga javob berishlari mumkin.

Plastic injection molding is a widely used manufacturing process for producing plastic parts in large quantities. It is a cost-effective and efficient method that allows for the production of complex shapes with high precision and accuracy. When it comes to plastic molding of lenses, achieving precision and quality is crucial to ensure optimal performance and functionality.

One of the key factors in achieving precision in plastic molding of lenses is the design of the mold. The mold must be carefully designed to accurately replicate the shape and dimensions of the lens. This requires the use of advanced CAD software and precise machining techniques to create a mold that can produce lenses with tight tolerances.

In addition to mold design, the selection of the right materials is also critical in achieving quality in plastic molding of lenses. The choice of material will depend on the specific requirements of the lens, such as optical clarity, impact resistance, and durability. Polycarbonate and acrylic are commonly used materials for lens molding due to their excellent optical properties and high impact resistance.

Once the mold design and material selection are finalized, the plastic injection molding process can begin. This process involves injecting molten plastic material into the mold cavity under high pressure. The material is then cooled and solidified to form the lens shape. It is important to closely monitor and control the temperature, pressure, and cooling rate during the molding process to ensure consistent quality and precision.

To further enhance precision and quality in plastic molding of lenses, post-processing techniques such as polishing and coating can be employed. Polishing the lens surface can improve optical clarity and reduce surface imperfections, while coating can enhance durability and resistance to scratches and abrasions.

Quality control is another crucial aspect of achieving precision in plastic molding of lenses. Inspecting the lenses for defects such as air bubbles, warping, or surface irregularities is essential to ensure that only high-quality lenses are produced. Automated inspection systems can be used to detect and reject defective lenses, ensuring that only flawless products are delivered to customers.

In conclusion, achieving precision and quality in plastic molding of lenses requires careful attention to detail in mold design, material selection, process control, post-processing, and quality control. By following best practices and utilizing advanced technologies, manufacturers can produce lenses that meet the highest standards of performance and reliability. Plastic injection molding continues to be a versatile and efficient method for producing high-quality lenses that are essential in various industries, including automotive, medical, and consumer electronics. With the right expertise and resources, manufacturers can achieve exceptional results in plastic molding of lenses and meet the demands of today’s competitive market.