Table of Contents

Advantages of Using Vertical Plastic Injection Molding Extruders

Vertical plastic injection molding extruders are a popular choice for manufacturers looking to produce high-quality plastic parts efficiently and effectively. These machines offer a number of advantages over horizontal injection molding machines, making them a preferred option for many in the industry.

One of the key advantages of vertical plastic injection molding extruders is their compact size. Unlike horizontal machines, which require a large amount of floor space, vertical extruders can be easily integrated into existing production lines without taking up a significant amount of room. This makes them ideal for manufacturers with limited space or those looking to maximize their production capacity.

In addition to their small footprint, vertical plastic injection molding extruders also offer improved accessibility. Operators can easily access the mold area from the front of the machine, making it easier to set up and monitor the production process. This increased accessibility can lead to faster setup times and reduced downtime, ultimately improving overall efficiency and productivity.

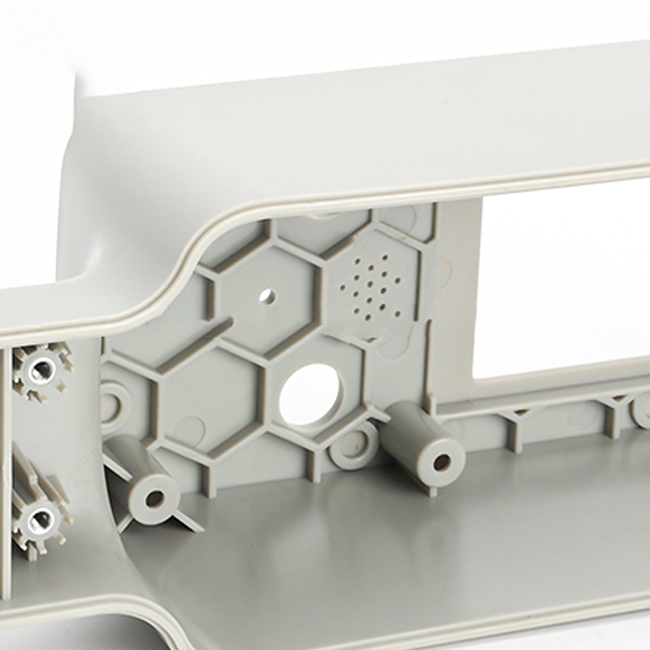

Another advantage of vertical extruders is their ability to produce complex parts with precision. The vertical orientation of the machine allows for better control over the injection process, resulting in more consistent and accurate parts. This is especially important for manufacturers producing intricate or detailed components that require tight tolerances.

Vertical plastic injection molding extruders also offer greater flexibility in terms of mold design. The vertical orientation of the machine allows for molds to be mounted on multiple sides, giving manufacturers the ability to produce a wider range of parts without the need for additional equipment. This versatility can help manufacturers save time and money by reducing the need for multiple machines or setups.

Furthermore, vertical extruders are often more energy-efficient than their horizontal counterparts. The vertical design of the machine allows for better heat distribution, reducing energy consumption and operating costs. This can lead to significant savings for manufacturers over time, making vertical plastic injection molding extruders a cost-effective option for many in the industry.

Overall, vertical plastic injection molding extruders offer a number of advantages over horizontal machines, including their compact size, improved accessibility, precision, flexibility, and energy efficiency. These machines are a popular choice for manufacturers looking to produce high-quality plastic parts efficiently and effectively. With their ability to produce complex parts with precision and flexibility, vertical extruders are a valuable asset for any manufacturing operation.

Common Challenges and Solutions in Vertical Plastic Injection Molding Extrusion Process

Vertical plastic injection molding extruders are a crucial component in the plastic manufacturing industry, allowing for the creation of a wide range of products with precision and efficiency. However, like any manufacturing process, there are common challenges that can arise during the extrusion process. In this article, we will explore some of these challenges and provide solutions to help overcome them.

One of the most common challenges in vertical plastic injection molding extrusion is material flow consistency. Inconsistent material flow can result in defects in the final product, such as warping or uneven thickness. To address this issue, it is important to ensure that the material is properly heated and mixed before it is injected into the mold. Additionally, adjusting the speed and pressure of the extruder can help to maintain a consistent flow of material throughout the process.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Another challenge that can arise in vertical plastic injection molding extrusion is mold cooling. Proper cooling is essential to ensure that the plastic solidifies evenly and quickly, preventing defects such as sink marks or warping. To address this challenge, it is important to monitor the temperature of the mold and adjust the cooling system as needed. Using a high-quality cooling system with precise temperature control can help to ensure that the plastic solidifies properly and results in a high-quality finished product.

In addition to material flow consistency and mold cooling, another common challenge in vertical plastic injection molding extrusion is mold release. If the plastic does not release from the mold easily, it can result in damage to the product or the mold itself. To address this challenge, it is important to use a high-quality mold release agent and ensure that the mold is properly cleaned and maintained. Additionally, adjusting the temperature and pressure of the extruder can help to ensure that the plastic releases from the mold smoothly.

One final challenge that can arise in vertical plastic injection molding extrusion is mold maintenance. Over time, molds can become worn or damaged, leading to defects in the final product. To address this challenge, it is important to regularly inspect and clean the mold, as well as make any necessary repairs or replacements. Additionally, using high-quality materials and proper maintenance techniques can help to extend the life of the mold and ensure consistent quality in the finished products.

In conclusion, vertical plastic injection molding extrusion is a complex process that requires careful attention to detail and precision. By addressing common challenges such as material flow consistency, mold cooling, mold release, and mold maintenance, manufacturers can ensure that their products are of the highest quality. By implementing these solutions, manufacturers can overcome these challenges and produce high-quality plastic products efficiently and effectively.